3

GB-049A_f.

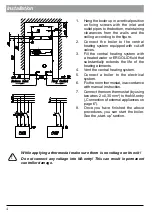

1. Read and strictly follow the installation and operating instructions to ensure a long

life and reliable boiler operation.

2. An efficient electrical installation which has been completed in accordance with the

binding norms of electric installation.

3. A wet central heating system equipped with appropriate expansion vessel made

according to the binding norms of hydraulic installation – closed system.

4. A wet central heating system must be flushed before boiler installation.

5. Do not install any barrier fittings (e.g. valves) on the outlet of the safety valve.

6. Its recommended for CH with thermostatic radiator valves to apply the differential

pressure relief valve (bypass). It allows the system to keep minimal flow of medium

through the boiler and reduces a noises in installation during the thermostatic valves

closing. The valve must be installed in by- pass conduit (before the boiler) according

to manufacturer’s instruction.

7. Boiler must not be installed in a humid place or in a place exposed to the danger

of explosion.

8. Boiler installation and all electrical and hydraulic work must be performed by

a qualified professional installer only.

9. All installation work must be performed when the power and water supply is cut off.

10. Electric installation should be equipped with residual current protective devices

and other solutions which will ensure disconnecting the heater from the source of

power (intervals between all their poles should not be less than 3 mm).

11. Do not drain the water from central heating system after the heating season.

12. Leave the controller in stand-by mode and do not cut off power supply between the

heating seasons.

Safety instructions