6

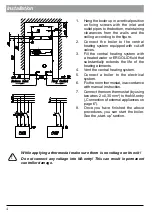

Room thermostat (NA entry) –

when the voltage

free contact gets opened the boiler will stop heating.

The entry is responsible for boiler control depending

on the room temperature.

Connection of external appliances

NA Q Twej Twyj

ZM

◦

◦ Termostat

pokojowy

Room

thermostat

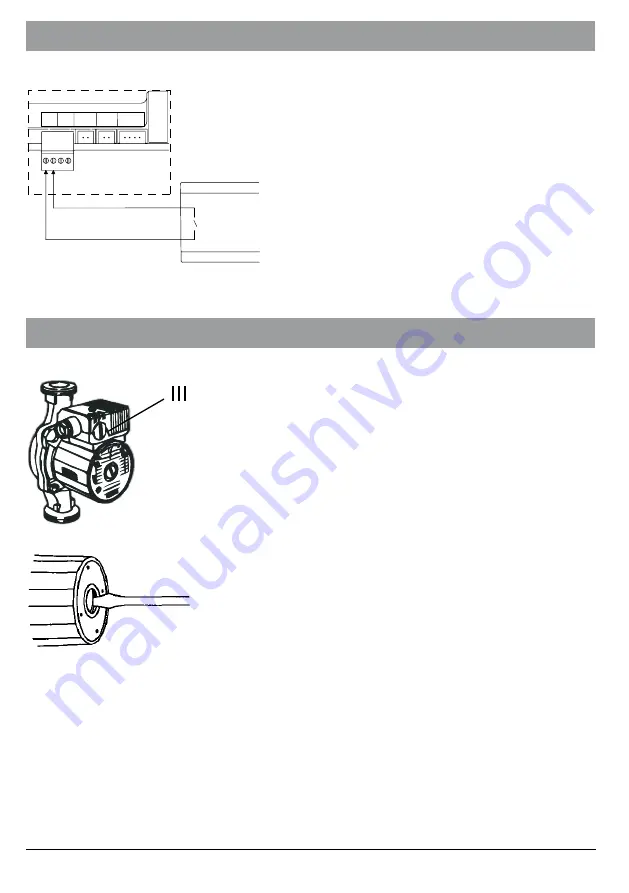

1. Disconnect the flat multi-conductor cable from ZM

entry of controller.

2. Switch the boiler on (button 1)

3. Connect the NA contacts

4. Set the temp. on max.

5. Make sure that a proper flow through the boiler is

reached („4” indicator is on with a constant light).

The pump should self vent after a short period of

running. if necessary assist the venting process in

the following way;

•

close the cut-off valve on the outlet,

•

set the pump on the highest gear,

•

undo carefully the vent plug on the pump,

•

after 15-30 s. do the vent plug up,

•

open the cut off plug,

6. Switch the boiler off (button 1), connect the flat multi- conductor cable into ZM entry

of controller

7. Connect the programmed room thermostat or connect the NA contacts.

8. Switch the boiler on (button 1).

9. Set the temperature of the medium at required temperature.

Start up