34

Experts in heating

User Manual

Twin Bio

- PLV 09.13

8

. Boiler operation and

m

aintenance

8. Boiler operation and maintenance

Use the main switch to deactivate the boiler and wait until

the boiler cools down – min. 1 hour before maintenance

(boiler cleaning).

8.A. Boiler operation guidelines

Normal daily boiler operation:

• check correct operation of system components: burner,

control system;

• check water level on a pressure gauge;

• check fuel level and quality and fuel feed system operation;

• check hydraulic joints leak tightness;

• keep the boiler room clean and tidy.

In case of any performance issues, remove the faulty devices

or contact an Authorised Service Centre to arrange a repair or

an adjustment.

8.B. Inspection scope and schedule:

a) Monthly

• check system water pressure

• check safety valve operation

• check control and safety device operation

• check tightness of all connectors and joints

• check balanced ventilation system

b) Minor inspection (every 6 months)

• check rope seal and gaskets,

• check boiler door thermal insulation,

• check safety devices (safety valve, safety temperature

limiter STB etc.),

• fl ue gas analysis (if a sudden increase in fl ue gas

temperature is identifi ed, the combustion part of the boiler

must be cleaned)

c) Major inspection (every 12 months)

• check rope seal and gaskets

• check boiler door and cleanout cover thermal insulation

• check safety devices (safety valve, safety temperature

limiter STB etc.)

• analyse fl ue gas

• clean combustion section of the boiler

• check thermal insulation of the boiler

• check and adjust burner, adjust control system settings

After a long boiler/burner downtime, the residual oxygen

in boiler water and the oxygen from the air mixed with carbonic

acid have highly corrosive properties. Take any precautions

necessary after if the boiler downtime lasted over a week.

Periodically remove the soot, sludge and ash from

the combustion chamber, the fl ue tubes and the grate. Clean

the boiler as necessary, but at least every 2 weeks. Remove

ash as required.

8.C. Maintenance

a) Boiler, burner, fuel feed system – mechanical

The regular and correct maintenance of the boiler is

a precondition of a correct and reliable operation and low fuel

consumption of the system. Contact an Authorised Service

Centre at least once a year and after every boiler downtime

to arrange an inspection.

Heating system maintenance procedure:

• deactivate the boiler (system) (stop mode);

• wait for a complete stop and allow to cool;

• reduce the boiler temperature to the level allowing safe

maintenance;

• open boiler door;

• clean combustion chamber and all fl ues and check the rope

seals in the boiler doors (replace if necessary);

• check and clean the burner (remove if necessary) – also,

clean the motor and fan (especially vanes) from the outside;

• close the boiler door with burner;

• remove the cover;

• clean the combustion products from the rear section

of the boiler;

• check cover gasket quality (rope seals) and remove

as required;

• close the rear boiler cleanout;

• check smoke duct condition and gas tightness;

• check installation and operation of the boiler sensors;

• check installation and operation of the fuel feed system;

• feeder gear motor;

• fuel feed ducts leak tightness and fl ow capacity.

Summary of Contents for 4062852055092

Page 1: ...E N G L I S H E N...

Page 2: ......

Page 4: ......

Page 41: ......

Page 42: ......

Page 43: ...D E U T S C H D E...

Page 44: ......

Page 46: ......

Page 83: ......

Page 84: ......

Page 85: ...R U...

Page 86: ......

Page 88: ......

Page 89: ...89 Twin Bio PLV 09 13 VI Twin Bio 1 2 3 4 Twin Bio 5 6 7 8 9 10 11 12 13...

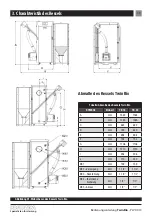

Page 96: ...96 Twin Bio PLV 09 13 4 Twin Bio 4 E A 1595 mm B 88 mm 02 1 2 3 4 1 2 3 4 02 4 H...

Page 97: ...97 Twin Bio PLV 09 13 4 Twin Bio 4 F KOSTRZEWA 286 Platinum Bio DX01 02 Twin Bio...

Page 100: ...100 Twin Bio PLV 09 13 5 5 5 A a A1 mm 500 B1 mm 700 C1 mm 500 H1 mm 2000 g mm 50...

Page 101: ...6 Uruchamianie 101 Twin Bio PLV 09 13 5 B 0 05 50 20x20 2 25 14x14 2 5 C 45 C 40 50 15 C...

Page 102: ...102 Twin Bio PLV 09 13 5 M M M c w u Platinum Bio GSM Twin Bio...

Page 103: ...103 Twin Bio PLV 09 13 5 c w u Platinum Bio M M M GSM Twin Bio...

Page 104: ...104 Twin Bio PLV 09 13 5 M M M Platinum Bio GSM Twin Bio c w u...

Page 107: ...107 Twin Bio PLV 09 13 5 6 5 G 5 H 6 6 A 6 B 5 D 30 C 6 C...

Page 108: ...108 Twin Bio PLV 09 13 6 6 D KOSTRZEWA www kostrzewa com pl ON 6 E...

Page 109: ...109 Twin Bio PLV 09 13 6 7 7 7 A...

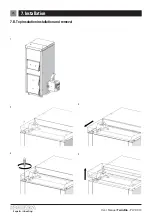

Page 110: ...110 Twin Bio PLV 09 13 7 7 B 1 2 3 4 5...

Page 111: ...111 Twin Bio PLV 09 13 7 7 C 1 2 3 4 5...

Page 112: ...112 Twin Bio PLV 09 13 7 7 D 1 2 3 4 5...

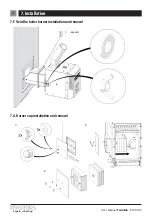

Page 113: ...113 Twin Bio PLV 09 13 7 7 E 1 2 3...

Page 114: ...114 Twin Bio PLV 09 13 7 7 F 1 7 G 1 2 3...

Page 116: ...116 Twin Bio PLV 09 13 7 7 J 2 1 2 1 1 2 3 4 5 6 7 K 200 C 1 OFF 2 3 4 5 6 7 8 ON 9 70 C 10...

Page 118: ...118 Twin Bio PLV 09 13 8 8 1 8 A 8 B a 6 STB 12 STB 1 Platinum Bio v02 2 8 C a...

Page 119: ...119 Twin Bio PLV 09 13 8 1 a 2...

Page 120: ...120 Twin Bio PLV 09 13 8 3 4...

Page 121: ...121 Twin Bio PLV 09 13 8 9 24 08 1991 81 11 06 2006 80 06 Platinum Bio 9 60 C...

Page 122: ...122 Twin Bio PLV 09 13 10 11 12 10 11 1 2 3 4 5 6 7 8 9 10 11 12 13 14 12 45 C...

Page 123: ...123 Twin Bio PLV 09 13 13 13 a STB STB...

Page 124: ...124 Twin Bio PLV 09 13 13...

Page 125: ......

Page 126: ......