39

38

7.5 WORK DEVICE

The work device consists of a boom, euro clamp and hydraulic cylinders.

It is pivotally attached via pins to the rear of the frame. The basic work tool is mounted on the front part of the boom using

the euro clamp. The boom is raised and lowered by a pair of hydraulic cylinders.

Another pair of hydraulic cylinders ensures the picking up and dumping of soil from the work tool (bucket).

7.6 CLAMPING ON ATTACHMENT

7.6.1 "EURO" QUICK CLAMP

1.

Before clamping, the clamping surfaces on the attachment and on the quick clamp must be cleaned of any dirt.

2.

The attachment to be clamped on must be placed with the bottom and the cutting edge on the ground so that

the cutting edge faces away from the machine.

3.

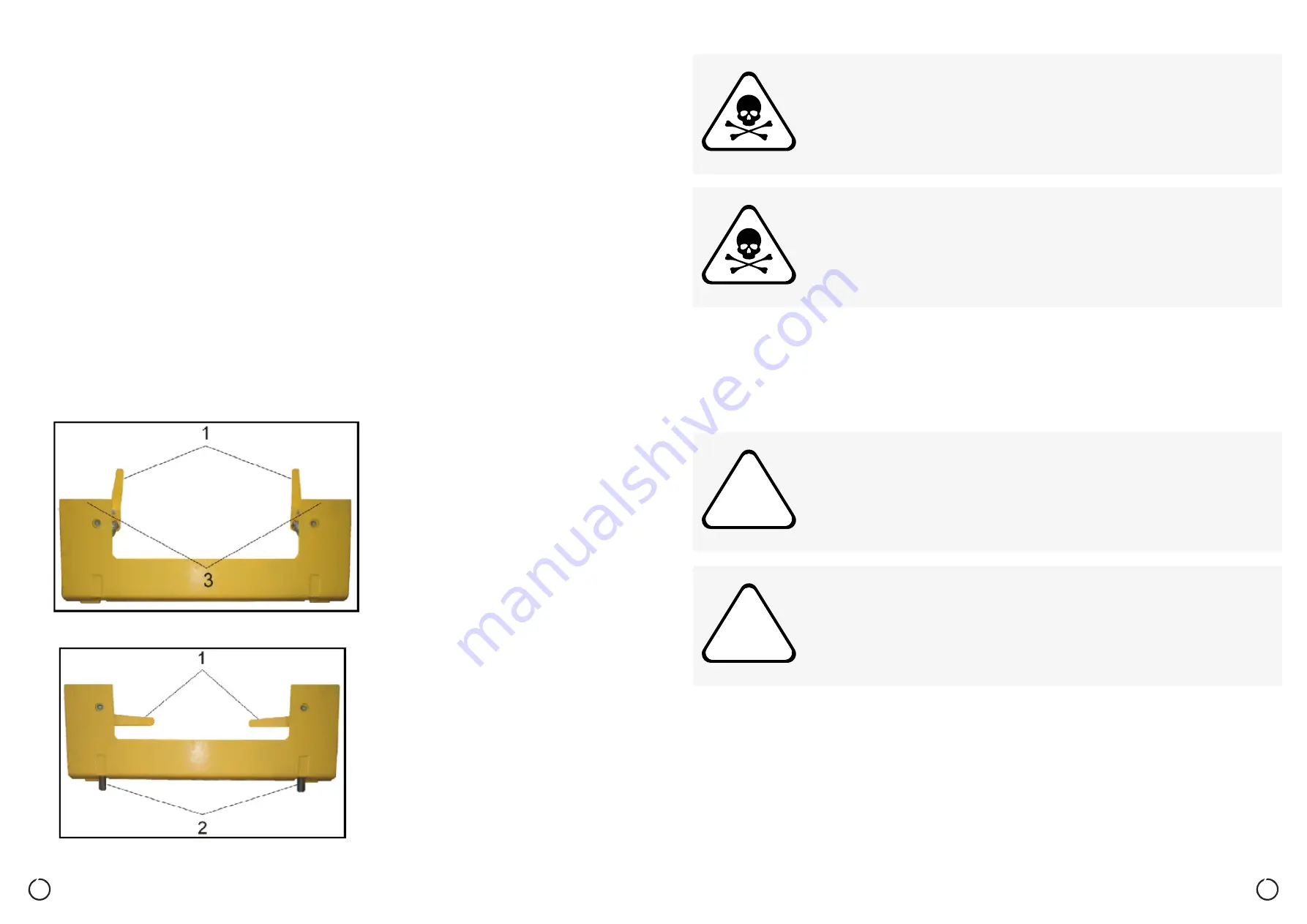

After flipping the levers (position 1 in Picture 7: released quick clamp) into vertical position, insert the quick clamp

by its pins (2).

4.

By handling the loader and the quick clamp, fit the clamping edges (3) of the quick coupler into the beds on the

attachment.

5.

Adjust the attachment by tilting the quick clamp so that the holes on the work tool are opposite the pins (2)

on the quick clamp.

6.

Secure the attachment by sliding the pins (2) into the holes on the work tool, and flip the levers (1) back to the orig-

inal (horizontal) position (Picture 8: quick clamp in secured position).

Picture 7

Picture 8

!

!

7.7 ELECTRICAL INSTALLATIONS

The electric drive of the loader is provided with a voltage of 96 V; all other appliances are in the 12 V version. The power

source are batteries located in the rear part of the frame. The appliances are protected by fuses. To control the appliances

and for monitoring operating data, the Kovaco mobile application is used, which is installed on a mobile phone or tablet.

The place for the mobile phone is on the right window, where it is fixed by a magnetic holder.

Danger

Improper clamping of the work tool can cause injury or death of persons. When the work tool

touches the ground, it may shift away from the clamp. Make sure that the work tool does not touch

the ground until the clamping pins are fully inserted.

Danger

By releasing the clamping pins of the mechanism, the mechanic (vehicle operator) loses control

over the work tool. Disconnecting the work tool when in an unstable position or when carrying

a load can result in a serious or fatal injury. Place the work tool in a safe position before releasing

the clamping pins.

Warning

The magnetic field radiating from the magnetic holder can damage mechanical watches.

Warning

In the event of a malfunction of any aspect of the electrical equipment, we recommend that you

first check the fuse for the relevant circuit.