5-4

Features of PID control

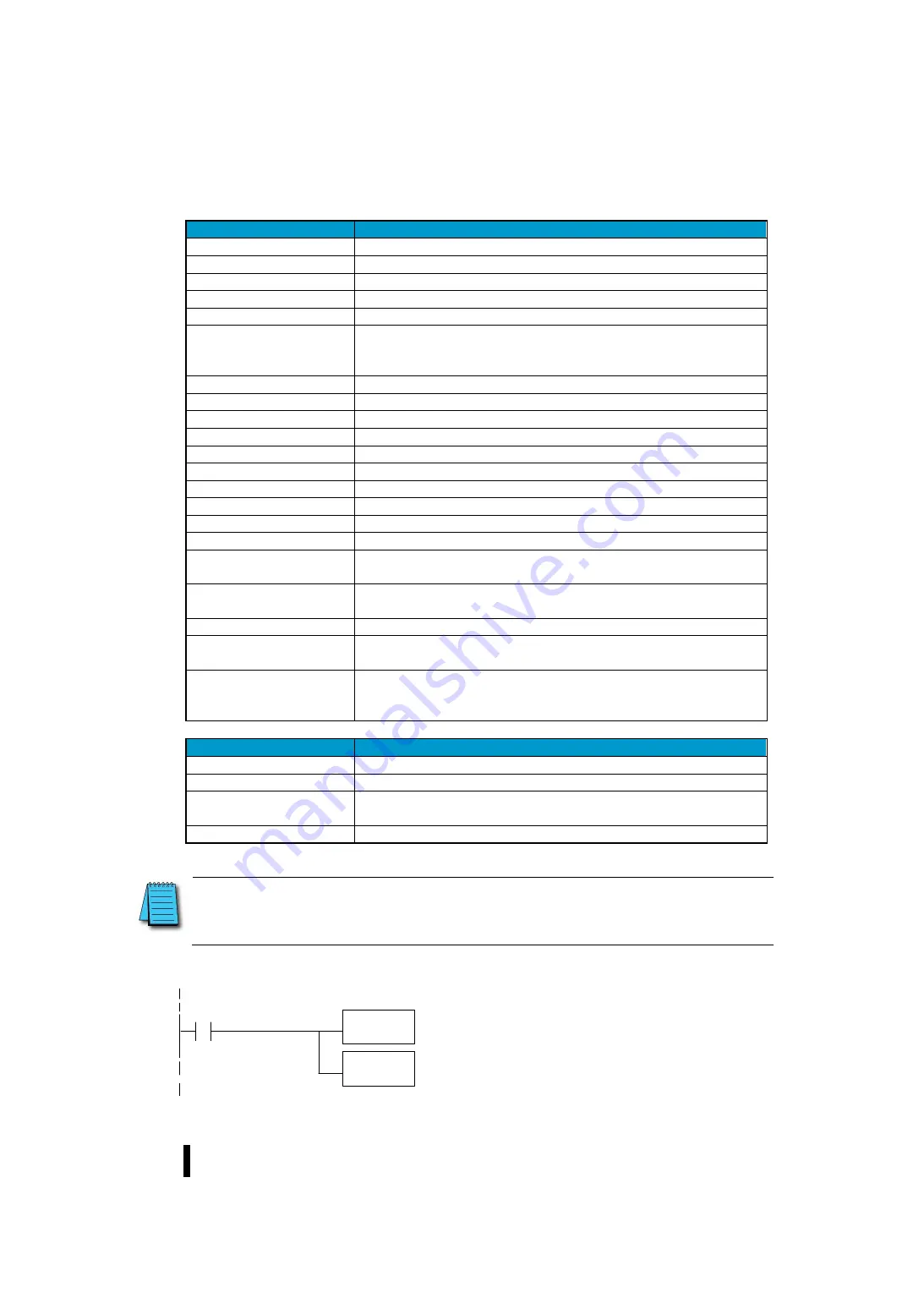

Specification

Number of loops

Selectable, up to 16 types

Required CPU register capacity

32 words per loop (register) or 64 words for lamp/soak

PID algorithm

Position or velocity form

Operating direction

Heating or cooling operation

Deviation curve

Select from the square of linear and deviation.

Sampling-period

(Time

interval

for

PID

calculation)

0.05 to 99.99 seconds (programmable by the user)

Minimum sampling period

0.05 seconds (1-16 loops)

Controlling mode

Automatic, manual, and cascade

Sink/soak generator

Up to 8 lamps/soak step per loop (16 categories)

PV curve

Standard linear or square root extraction (for flow meter input)

Set point (target value)

Minimum/Maximum set point value is specified.

Output value (measured value)

Minimum/Maximum output value is specified.

Gain (proportional)

Specify gain 0.01 to 99.99.

RESET (INTEGRATION) TIME

Reset time 0.1 to 999.8 (in seconds or minutes)

Rate (derivative) time

Specify the differential time from 0.01 to 99.99 seconds.

Differential filter constant

Specify the differential filter constants 1 to 20.

Bumper transfer I

When switching manual control to automatic control,

Bias and set points are automatically initialized.

Bumper transfer II

When switching manual control to automatic control, the bias equal to control output is

automatically set.

Step bias

The bias can be adjusted in proportion to the large variation of the set point.

Reset windup

When the control output reaches 0% or 100%, the integrator is disabled (to prevent

significant overshooting due to integral operation).

Zone of insensitivity of deviation

Specify the tolerance (plus/minus) for the deviation (SP-PV). This area does not cause

an error, and the control output value is calculated.

When the deviation is within this range, the deviation is controlled as zero

Alarming function

Specification

Dead-band

Alarm insensitivity zone (0.1%-5%) for all alarms is specified.

PV alarm

Set PV alarm settings for low-low, low, High, and High-high conditions.

PV deviation

Deviation alarm shown as the difference between the PV value (measured value) and the

SP value (target value)

Rate of the change

PV detects a user-specified value violation

Note: When analogue input/output of the SJ Ether unit is used, go to special register R7640 (analogue input/output

setting register)

Set the data format to "BIN".

On the PID setting/PID monitor of KPP, use the "BCD" format.

アナログ入出力データのデータ形式をBIN形式設定とする値を設定。

※入出力タイプ指定は、使用機器に応じた設定としてください。

ここでは、電圧に設定しています。

アナログ入出力データフォーマット、入出力タイプ格納特殊レジス

タへ設定値を書き込む

SP0

LDS

KE000

OUTW

R7600

Set the value whose the data format of analog I/O data is BIN format setting.

*The setting of I/O type specification should be suitable for the device you use.

It is set to voltage here.

Write the set value to the data format of analog I/O and I/O type storage special

register.

Summary of Contents for Kostac SJ-Ether Series

Page 1: ...English version of the KOSTAC SJ Ether series user s manual SJ ETHER USER M...

Page 12: ......

Page 13: ...1...

Page 14: ......

Page 88: ......

Page 89: ......

Page 113: ...3 24 Note Refer to 6 3 3 Module Assembly for connections and locks between modules...

Page 153: ......

Page 156: ...flashing OFF Not sent H W RX Green flashing Receiving H W OFF Not received H W...

Page 161: ...4 8...

Page 221: ......

Page 310: ...Chapter 7 Maintenance...

Page 311: ......