Page 19

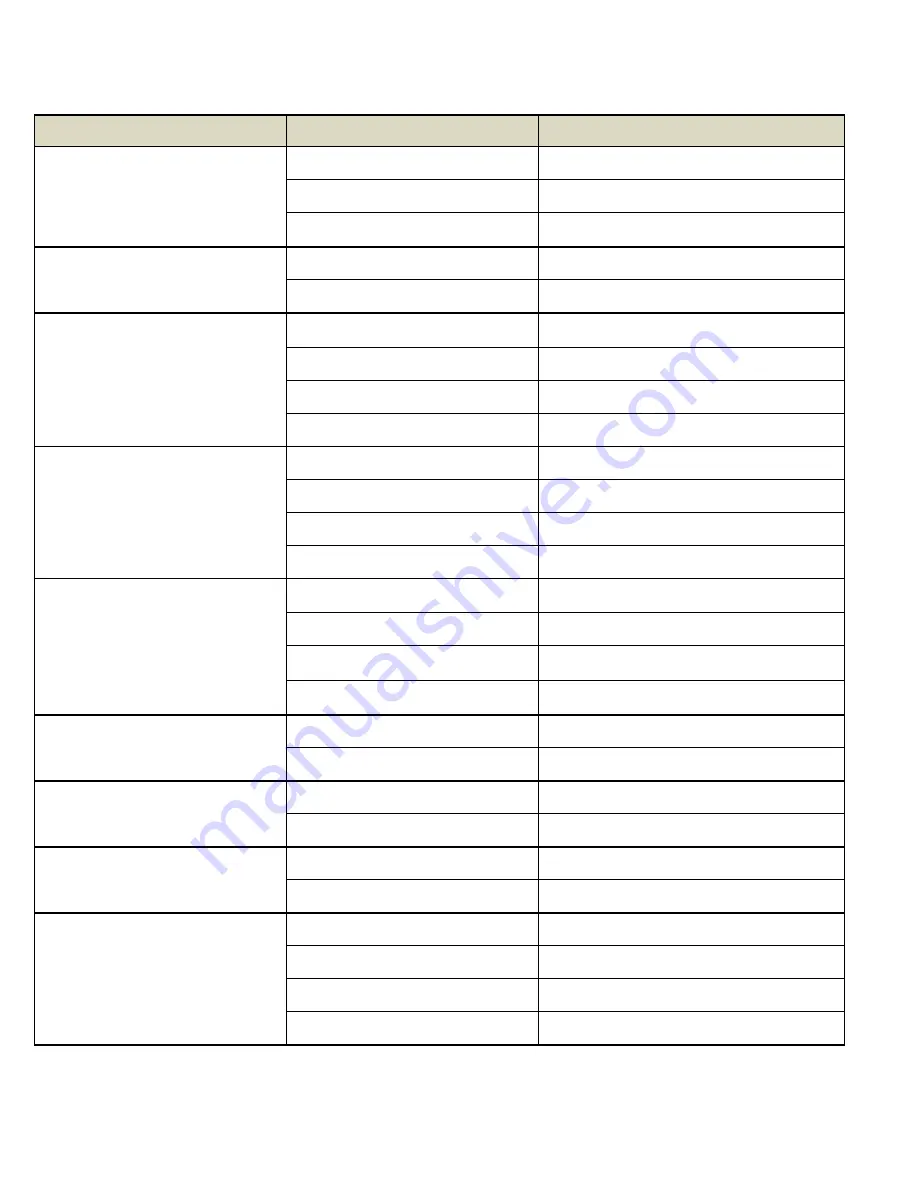

TROUBLESHOOTING

FAILURE

CAUSE

REMEDY

Dark screen

Emergency switch turned OFF

Turn it ON

Safety Temperature Limiter has relased

Let the boiler cool down to 80

°

C

Reset the Safety Temperature Limiter and search for

cause (e.g. Defect pump..)

Error: Out of Pellets

No more pellets in fuel hooper

Refill

Defective pellet level sensor

> Inform customer service

Error: Ignition failed

Too cold ambient temperature

The ambient temperature should be 0-45

°

C for

proper working

Low quality pellets

Change pellets

Ignition device malfunction

> Inform customer service

Exhaust fan malfunction

> Inform customer service

Error: Overtemperature detected

Boiler temperature exceed 95

°

C

Let the boiler cool down

Circulation pump malfunction

> Inform customer service

Defective controlled board

> Inform customer service

Defective temperature sensor

> Inform customer service

Error: Back burning to auger

The temperature of the auger exceeded

the limit thermostat's value

Back burning to auger

Defective back burning detection

thermostat

> Inform customer service

Lost connectivity between the controller

and back burning detection thermostat

> Inform customer service

Error: Memory allocation error

Problem occured in the control panel

Reset controller

If the problem persists after reset

> Inform customer service

Error: FLASH checksum error

Problem occured in the control panel

Reset controller

If the problem persists after reset

> Inform customer service

Error: FILESYSTEM error

Problem occured in the control panel

Reset controller

If the problem persists after reset

> Inform customer service

Error: Sensor malfunction (

sensor no

)

T3: Boiler - Defective sensor

> Inform customer service

T2: Weather - Defective sensor

> Inform customer service

T1: Buffer tank - Defective sensor

> Inform customer service

Tc1: Exhaust - Defective sensor

> Inform customer service

Summary of Contents for SLIMPEL

Page 8: ...Page 8 SPECIFICATIONS SLIMPEL 25...

Page 9: ...Page 9 SLIMPEL 40...

Page 10: ...Page 10 AIR ELIMINATOR VALVE BLOW OFF...

Page 14: ...Page 14 This page intentionally left blank...

Page 21: ...Page 21...