OM45T_

Rev N

Page 9

1.2 A-325 Tensioning Procedure

Throughout the installation instructions, there will be several references to the A-325 hardware tensioning

procedure. The A-325 hardware must be properly tensioned to avoid slippage between bolted surfaces under

high loads. Slippage can cause the corresponding assembly to move or slip, resulting in antenna misalignment.

Use of A-325 hardware eliminates slippage between mating surfaces under high loading conditions as well as

the need for future retightening.

NOTE:

A-325 tensioning is for

final connections ONLY

.

NEVER LOOSEN OR REUSE A-325 HARDWARE

.

Points to Keep in Mind:

•

“Snug tight” is defined as tightness when plies of joint are in firm contact

•

Do not proceed with felt-tip marker or tightening unless connection is final and will not be loosened again

•

If after tensioning procedure the bolts are loose, discard them and replace with new hardware

•

Do NOT use A-325 tensioning

UNLESS SPECIFICALLY CALLED FOR BY INSTALLATION

INSTRUCTIONS

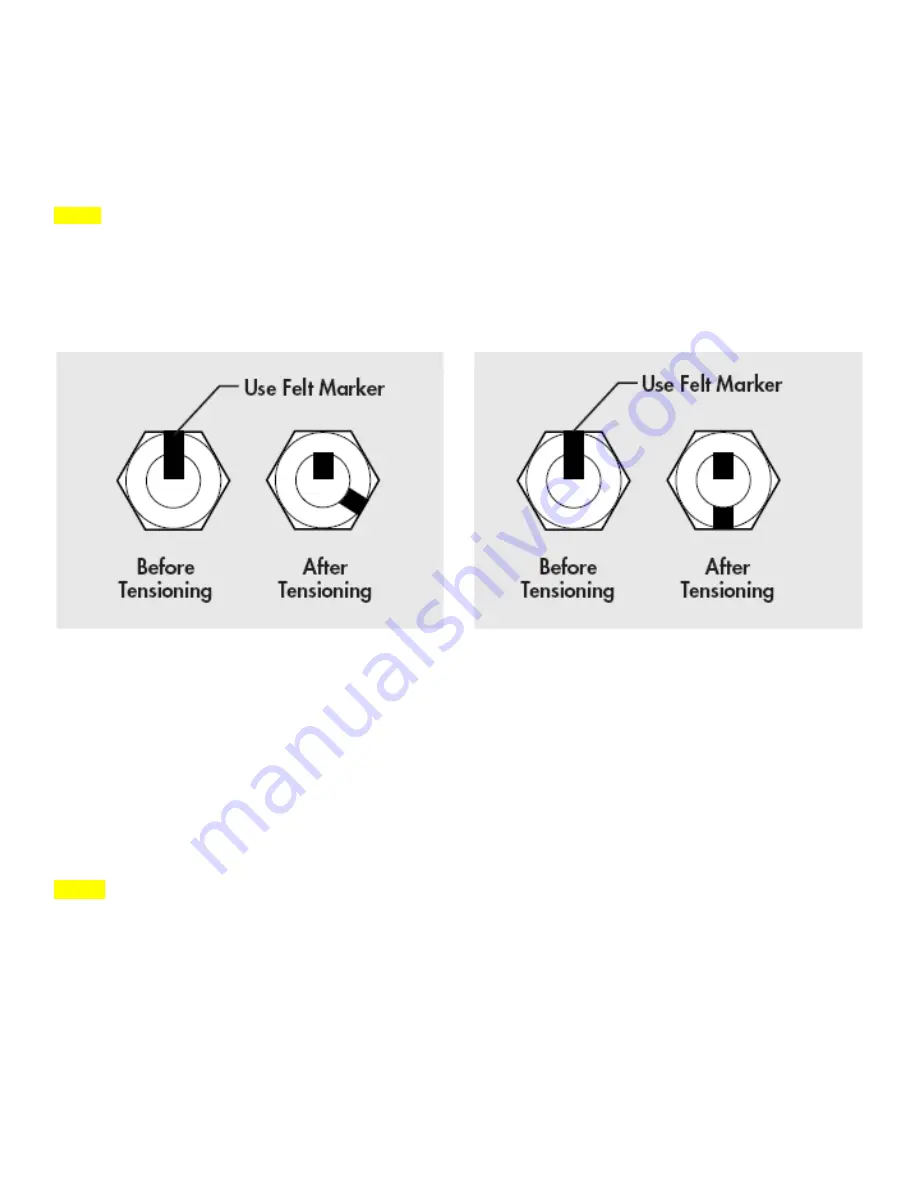

Figure 1-1a:

Figure 1-1b:

Bolts Shorter than 4 Diameters

Bolts Longer than 4 Diameters

A-325 hardware should be tightened according to the following tensioning procedure:

Step 1.

LUBRICATE

the bolts with

PROVIDED WAX STICK

to reduce friction

Step 2.

INSERT THE BOLT

and

ADD FLAT WASHER

(if required).

DO NOT

allow wax to get under flat

washer

Step 3.

ADD THE NUT

, and

TIGHTEN WITH YOUR FINGERS

Step 4.

After all connections are complete,

TIGHTEN THE BOLTS

until surfaces are joined and nuts are

snug (for example, as

achieved by the full effort of a SINGLE person using a standard spud

wrench

)

NOTE:

If A-325 bolts are loosened

AFTER

STEPS 5 and/or 6

,

DISCARD & REPLACE

with

NEW hardware

Step 5.

Using a

FELT-TIP MARKER

, mark the nuts and ends of the bolts with a straight line as shown above

in

Figures

1-1a

(Bolts

shorter

than 4 diameters

) and

1-1b

(Bolts

longer than 4 diameters

)

Step 6.

TIGHTEN NUTS EVEN FURTHER

, using an

EXTRA-LONG-HANDLED WRENCH

, until the nuts are:

•

MOVED 1/3 TURN (120°)

as shown in

Figure

1-1a,

for

bolts

shorter

than 4 diameters

(“After

Tensioning”)

Or

•

1/2 TURN (180°)

as shown in

Figure

1-1b,

for

bolts

longer than 4 diameters

(“After Tensioning”)