14

8506

KRAUSMANN POWER TOOLS

1

2

5

2

Hole

Hole

English |

EN

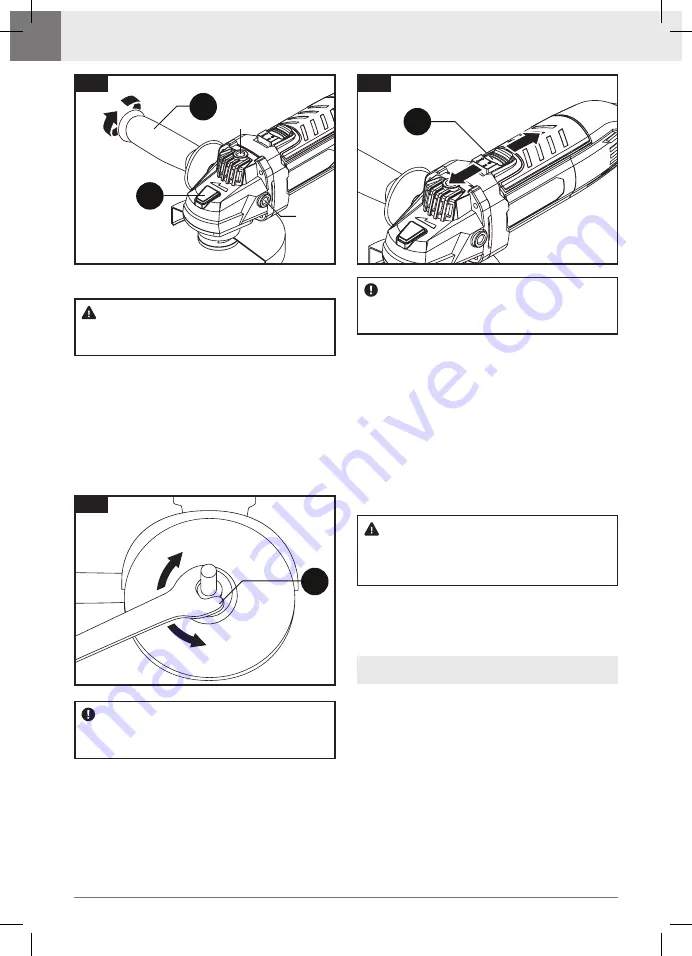

Installing and removing a disc

Turn the angle grinder on to its back and press the

spindle lock button and rotate the spindle until it

locks. Install the spacer on the axle. Place the disc

on the spacer. Screw the tension nut to the axle.

Press the spindle lock button

2

(fig 2) and tighten

the tension nut using the wrench

6

(fig 3). Release

the spindle lock button. To remove the disc, follow

the procedure in reversed order.

WARNING:

Before installing or removing a disc always remove the

tool from the plug.

fig 2

6

fig 3

Using the tool

Switching ON and OFF

CAUTION:

D

o not use excessive force to clamp the disc. It could crack

it and cause failure during use.

WARNING:

T

he disc continues to turn for a few seconds even though

the switch is turned off. Keep your hands well away from

the moving disc.

fig 4

To switch the tool on, push the ON / OFF switch

1

towards the disc. To turn the tool off, push the

ON / OFF switch

1

towards the rear part of the

machine (fig 4).

This function prevents the tool from turning on in

case a voltage drop has occured.

Start the grinder and let it reach its full speed

before you begin working. While grinding, hold the

grinder at approximately 15° to 30º to the work

area. Do not exert side pressure on the disc.

Follow all the precautions in this manual and keep

a steady even pressure when you work. Remem-

ber that there is always the possibility that the disc

could fracture so do not force the tool.

When you have finished, switch off and unplug

the tool.

Voltage drop protection function

CAUTION:

Never engage the spindle lock whilst the spindle is

rotating.

5. Maintenance

For safe and proper working, always keep the tool

and ventilation slots clean.

Τhe tool may be cleaned most effectively with com-

pressed dry air.

Always wear safety goggles when

cleaning tools with compressed air.

Certain cleaning agents and solvents damage

plastic parts.

Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia

and household detergents that contain ammonia.

T

he brushes and commutator in your tool have been

engineered for many hours of dependable service. To

Summary of Contents for 8506

Page 2: ...2 8506 KRAUSMANN POWER TOOLS ON OFF 1 2 3 6 7 8 1 GR 4 3 5 2 1 4 6 2 3 8 7 5...

Page 3: ...3 KRAUSMANN POWER TOOLS 8506 GR OFF...

Page 4: ...4 8506 KRAUSMANN POWER TOOLS GR ON OFF 3 1 2 3 4 5...

Page 5: ...5 KRAUSMANN POWER TOOLS 8506 GR M 10 11 12 13 14 6 7 8 9 80 M X E...

Page 7: ...7 KRAUSMANN POWER TOOLS 8506 1 6 GR 2 2 6 3 ON OFF 3 4 ON OFF 1 ON OFF 1 4 15 30 OFF ON...

Page 8: ...8 8506 KRAUSMANN POWER TOOLS GR 6 T T X K 7 5...

Page 16: ...16 8506 KRAUSMANN POWER TOOLS 8506 www krausmann gr...