Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

Automatic spray gun

RA-2 HV3

for adapter with

material

pressure regulator,

article no.

0909-080-0681

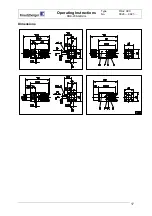

0921-090-2370 0921-090-2369 0921-090-2372 0921-090-2371

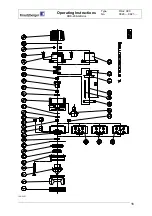

3. Assembly

The assembly of the automatic spray gun type RA-2 HV3 depends on the intended

application. We recommend the screw connection with the retaining bolt, art. no. 6922-080-

1256 as a standard fixing system. Further mounting/assembly options are shown in the

diagram 140-0019 - e.g. mounting on the adapters (101 to 103).

Note

If the automatic spray gun is not adequately secured, it may become loose during operation

- e.g. due to vibrations. There is also a risk of displacement due to recoil. Under certain

circumstances, the coating substance may escape in an uncontrolled manner.

Caution

Assembly should be performed by suitably trained personnel only!

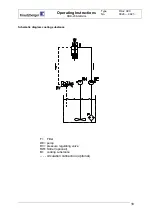

4. Startup

4.1 Connections

Control air to input (St); (symbol stamped next to connection)

Circular jet air to input (R); (symbol stamped next to connection)

Flat jet air to input (F); (symbol stamped next to connection)

Material connection to input (M); (symbol stamped next to connection)

Caution

Compressed air and material feed should only be connected up by suitably trained

personnel! Ensure that the pressures and temperatures listed under "Technical Data" are

not exceeded!

Notes

Air and material feed are connected via internal threads (e.g. nipple or nozzle-type

connection depending on application). If you not sure about the best connection method,

consult your supplier or Krautzberger GmbH.

Material feed can be effected via a container (under the intrinsic hydrostatic pressure of

the coating substance), a pressurised container or pumps. Circulation connection is

possible (e.g. when applying settling coating substances).

In the case of material feed under pressure (e.g. from pressure containers or via pumps),

5

ensure that the material feed is interrupted if the atomiser air pressure falls rapidly due