Type

RA-2 HV3

Operating Instructions

DOK-208-GB.doc

No. 0920-..,

0921-...

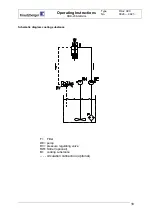

to, for example, loosening of a hose connection, bursting of the hose or similar.

Without atomiser air feed, the range of the material jet may be multiplied many times,

depending on the material! It is important to ensure that the control air is immediately

interrupted if there is a fall in atomiser air pressure in order to prevent material discharge.

In particularly critical cases, a spray jet monitor should be installed (using, for example, a

light barrier or a pressure monitor directly in front of the automatic spray gun - in other

words,

behind

the control element (valve or regulator)). The spray jet monitor must be

switched in such a way that the entire air feed is interrupted if there is a rapid fall in

atomiser air pressure. This also ensures interruption of the material feed.

The automatic spray gun RA-2 HV3 must always be operated using filtered air.

Both the circular jet air pressure and (where applicable) the flat jet air pressure should be

regulated via a proportional regulating valve or a pressure reducer.

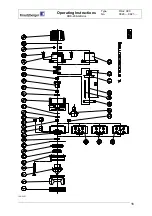

Checking the connections

Interrupt

material feed

control air supply

circular jet air supply and

flat jet air supply.

No air or material must be discharged from the automatic spray gun type RA-2 HV3.

Where present, open the adjusting nut (36) of the needle stroke adjuster (see section

5.2, Mode of operation/Spray profile adjustment)

Open control air supply (the needle in the material nozzle must retract)

Open circular jet air pressure (air must flow out of the central borehole of the circular

or flat jet air nozzle)

Close circular jet air supply

Open flat jet air supply (air must flow out of the humped boreholes of the flat jet air

nozzle)

Close air supply

Connect or open material supply

Neither air nor material must be discharged from the automatic spray gun type RA-2 HV3.

Caution

Prior to starting work, ensure that the control air connection and the atomiser air

connections have not been interchanged! Risk of uncontrolled material discharge!

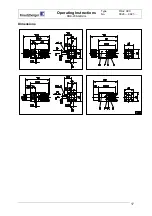

4.2 Mode of operation / Spray profile adjustment

Close control air supply

"Open" material feed (see following instructions)

Open circular jet air supply

Open flat jet air supply

Open control air supply (material needle (39 or 40) is pushed back by the air pressure

and releases the material flow)

The coating substance is sprayed. It is generally now necessary to adjust the spray profile.

If present, open the adjusting nut (36) of the needle stroke adjuster (see following

instructions)

6