BETRIEBSANLEITUNG

Dokument: DOK-029

VORSICHT!

BEIM ARBEITEN MIT EINER DÜSENVERLÄNGERUNG

BEACHTEN, DASS SICH AUS BRENNBAREN MATE-

RIALIEN UND LUFT IN HOHLRÄUMEN BESONDERS

LEICHT EXPLOSIVE GEMISCHE BILDEN KÖNNEN!

FÜR AUSREICHENDE ENTLÜFTUNG SORGEN!

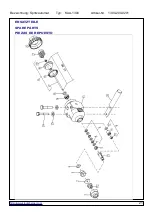

Vorzerstäuberdüse

Die Vorzerstäuberdüse beschleunigt den Materialfluss

und trägt zur Verbesserung des Spritzbildes bei. Es kann

mit z. T. beträchtlich geringerem Materialdruck und/oder

größerer Materialdüse gearbeitet werden. Mit einer grö-

ßeren Materialdüse - und entsprechend langsamerer

Durchflussgeschwindigkeit - verringert sich die Verstop-

fungsgefahr.

Die Vorzerstäuberdüse ist jeweils auf die Materialdüsen-

größe abzustimmen (siehe hierzu Tabelle Airless-Düsen

im Bestellkatalog der Krautzberger GmbH). Die Vorzer-

stäuberdüse (111) wird unmittelbar hinter der Material-

düse (112), statt der Dichtung (2), montiert.

HAZARD AND WARNING NOTES!

O

NLY START UP THE AUTOMATIC SPRAY GUN

AFTER CAREFULLY READING THE OPERATING

INSTRUCTIONS IN FULL!

ASSEMBLY OF THE AUTOMATIC SPRAY GUN AND

CONNECTION OF THE MATERIAL FEED SHOULD BE

EFFECTED ONLY BY SUITABLY QUALIFIED PERSON-

NEL! CHECK THE MOUNTING DEVICE, PRESSURE

HOSES AND THE CONNECTIONS FROM TIME TO

TIME!

ALWAYS WEAR THE PROTECTIVE EQUIPMENT (E.G.

PROTECTIVE CLOTHING, GOGGLES, BREATHING

PROTECTION, GLOVES ETC.) RECOMMENDED BY

THE SUPPLIER OF THE COATING SUBSTANCE

DURING MAINTENANCE, CLEANING OR REPAIR

WORK AND WHEN CHANGING MATERIALS! WEAR

EAR MUFFLERS IF NECESSARY!

COMPLY WITH THE EXPLOSION PROTECTION

REGULATIONS WHEN USING POTENTIALLY FLAM-

MABLE AND EXPLOSIVE COATING SUBSTANCES!

KEEP AWAY FROM SOURCES OF IGNITION AND

OPEN FLAMES!

WHEN USING SUBSTANCES SUCH AS SOLVENTS

WHICH CAN GENERATE AN INCREASED EXPLOSI-

ON POTENTIAL DUE TO ATOMISATION OR SPRAY-

ING IN AIR, TAKE PROTECTIVE MEASURES AND

EFFECT SPECIAL NOTIFICATION OF THE PARTICU-

LAR HAZARD! IN CASE OF DOUBT, CONSULT THE

SUPPLIER OF THE COMPONENTS! COMPLY WITH

THE WARNING AND HAZARD INSTRUCTIONS OF

THE SUPPLIER OF THE COATING MATERIAL AND

THE DETERGENT WITH REGARD TO EMISSION,

FIRE OR EXPLOSION HAZARD OR OTHER HAZARDS

(WHERE APPLICABLE)! IN CASE OF DOUBT, CON-

SULT THE SUPPLIER(S) OF THE COMPONENTS IN

QUESTION!

WHEN MIXING DIFFERENT COMPONENTS AND/OR

WHEN USING SOLVENTS OR THINNING AGENTS TO

MAKE COATING MATERIALS, TAKE STEPS TO ENSU-

RE THAT NO SUBSTANCES WITH INCREASED

HAZARD POTENTIAL ARE CREATED (E.G. FLAMMA-

BILITY, EXPLOSION HAZARD, INCREASED EXPLOSI-

VE TENDENCY THROUGH SPRAYING IN AIR, TOXI-

CITY, INCREASED TOXICITY DUE TO CHEMICAL

REACTION WITH AIR ETC.)! AVOID INCREASED

HAZARD POTENTIAL CAUSED BY UNDESIRED CHE-

MICAL REACTIONS! WHERE NECESSARY, TAKE

PROTECTIVE MEASURES AND EFFECT SPECIAL

NOTIFICATION OF THE PARTICULAR HAZARD! IN

CASE OF DOUBT, CONSULT THE SUPPLIER(S) OF

THE COMPONENTS IN QUESTION!

THE COMPATIBILITY OF THE PARTS OF THE AUTO-

MATIC SPRAY GUN WHICH COME INTO CONTACT

WITH THE MATERIAL CANNOT BE GUARANTEED

FOR ALL POTENTIAL COATING SUBSTANCES (SEE

CHART “PARTS IN CONTACT WITH THE MATERIAL”

IN SECTION 11, TECHNICAL DATA). IN CASE OF

DOUBT, CONSULT KRAUTZBERGER GMBH!

(!) UNDER NO CIRCUMSTANCES SHOULD THE

SPRAY JET BE DIRECTED AT PEOPLE OR ANIMALS!

THE JET CAN PENETRATE THE SKIN, ENTER THE

BODY AND FORCE AIR INTO THE ORGANISM. RISK

OF FATAL EMBOLISM!

THE MATERIAL JET IS PARTI-

CULARLY DANGEROUS IF NO AIRLESS NOZZLE IS

MOUNTED

AND THE JET IS DISCHARGED DIRECTLY

FROM THE VALVE SEAT SCREW!

THERE IS ALSO THE RISK OF POISONING WHEN

USING POISONOUS COATING SUBSTANCES OR

DETERGENTS!

SET UP AN EMERGENCY FIRST AID

UNIT IN THE PLANT!

WHAT DO TO IN THE CASE OF AN ACCIDENT: IMME-

DIATE MEASURES:

CORRECT TREATMENT OF

WOUNDS.

FURTHER

MEASURES:

IMMEDIATE

TREATMENT BY AN EMERGENCY SERVICE DOCTOR

WHO HAS BEEN INFORMED OF THE SUBSTANCE

USED. DO NOT STAND IN THE AREA OF THE MATE-

RIAL JET!

NEVER DIRECT THE SPRAY JET AT ELECTRICAL

SYSTEMS OR EQUIPMENT!

DO NOT SPRAY WORKPIECES OR SURFACES

WHICH ARE INSUFFICIENTLY STABLE! THE HIGH-

ENGLISH

10