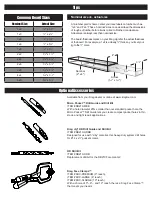

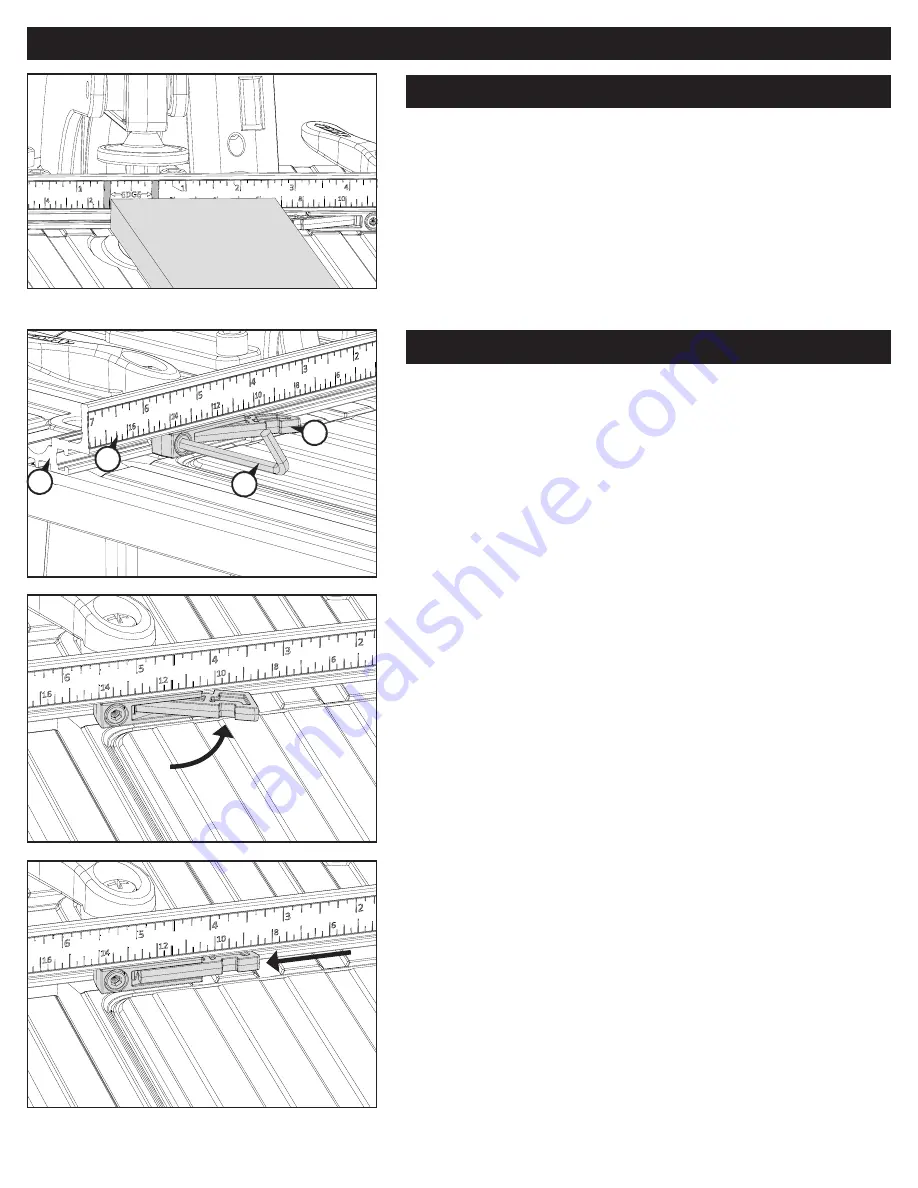

Operation

In addition to the proper machine settings, proper spacing of pocket

holes in the workpiece is important for making a strong joint. For

narrow parts such as rails, stiles and frames, locate pocket holes ⅜" to

½" from each edge. Shaded lines on the measuring tape indicate this

offset, eliminating the need to mark pocket-hole locations. Simply align

the edge of your workpiece with the shaded line and drill. For wide

parts such as panels and table tops, place the first pocket hole 2" from

the edge and every 6" on center after that.

Pocket-hole placement

A workpiece stop can be used on either side of the drill guide by

sliding it out of the fence T-slot, flipping it over so the open end

of the stop arm faces center, and reinstalling it in the T-slot.

Loosen the socket-head bolt on the workpiece stop (32) with the

3mm hex wrench (13), slide the stop to the desired location, and

tighten the bolt. Keeping the fence (16) centered side to side allows

you to use the center-reading measuring tape (33) to position the

stops. Override a stop by placing the workpiece over the stop,

pressing the spring-loaded stop arm into the stop body.

Each stop arm can be held in the retracted position by pressing

the arm into the stop body and then sliding it toward the socket-

head bolt that secures the stop in the fence. The notch in the arm

provides a grip point. To reactivate the stop arm, slide it away from

the bolt.

Workpiece stops

16

13

33

32