KREMLIN REXSON

Page 3

Manual : 574.107.112

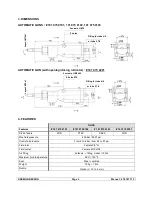

PICTOGRAMS

A

D

F

E

C

G

Nip hazard

Warning moving

elevator

Warning moving

parts

Warning moving

shovel

Do not exceed

this pressure

High pressure

hazard

H

J

L

K

M

Q

Relief or drain

valve

Warning hose

under pressure

Wear of glasses

is obligatory

Wear of gloves is

obligatory

Product vapor

hazard

Warning hot parts

or areas

N

P

R

Electrical hazard

Warning fire

hazards

Explosion

hazards

Grounding

Warning (User)

Warning serious

injuries

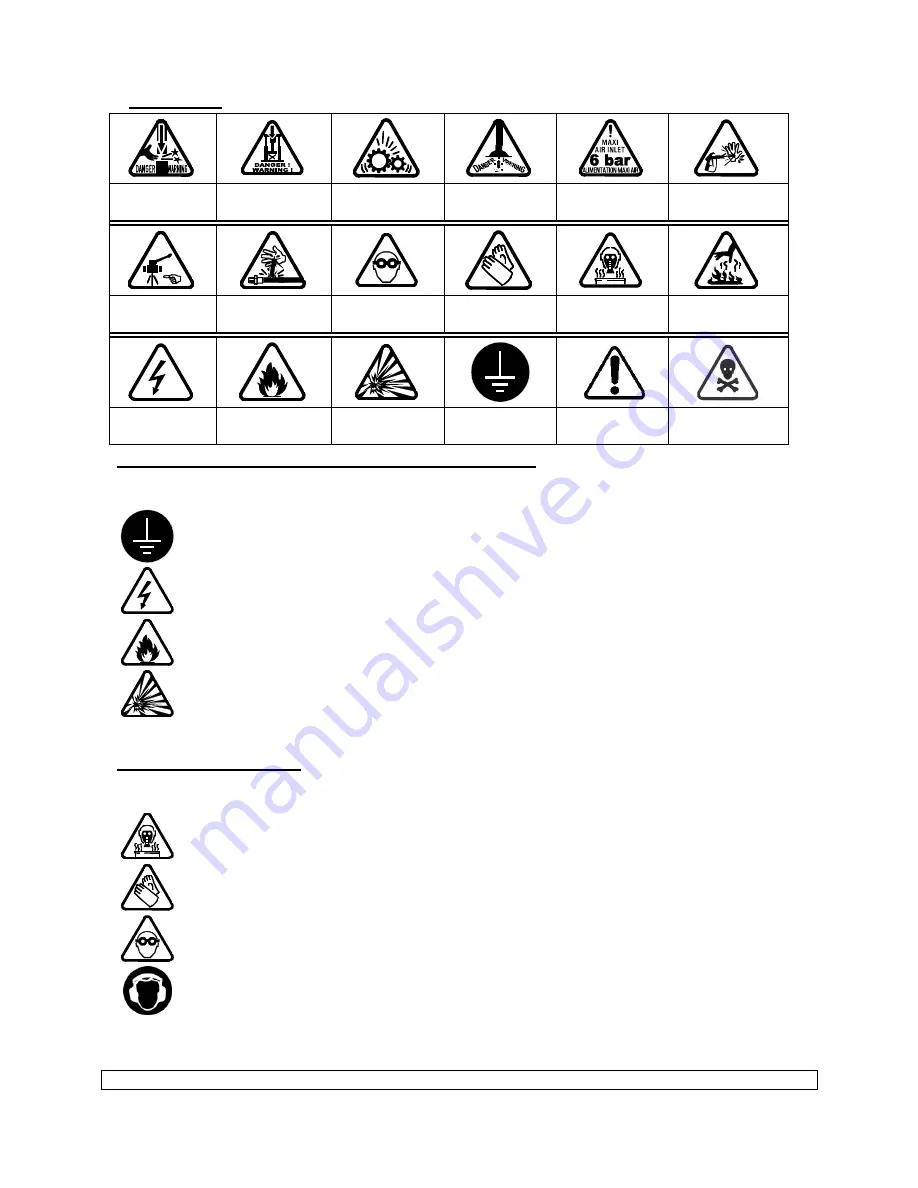

FIRE - EXPLOSION - SPARKS - STATIC ELECTRICITY HAZARDS

A poor earth connection, inadequate ventilation, sparks or static electricity can cause an

explosion or fire. to avoid these risks when using or servicing KREMLIN REXSON equipment,

the following safety procedures must be followed :

ensure a good earth connection and ground the parts to be handled i.e. solvents,

materials, components and equipment,

ensure adequate ventilation,

keep working area clean and free from waste solvents, chemicals, or solid waste i.e.

rags, paper and empty chemicals drums,

never use electrical switches / power if in an atmosphere of volatile solvent vapour,

stop working immediately in case of electrical arcs,

never store chemicals and solvents in the working area.

use paint whose flash point is the highest possible to prevent from any formation of gas

and inflammable vapours (refer to materials' safety instructions),

install a cover on the drums to reduce the diffusion of gas and vapours in the

spraybooth.

TOXIC PRODUCT HAZARDS

Toxic products or vapours can cause severe injury not only though contact with the body, but

also if the products are ingested or inhaled. It is imperative :

to know the material products and their risks,

notified or hazardous materials must be stored in accordance with the regulations,

the material must be stored in an appropriate container, never place materials in a

container where there is a risk of spillage or leakage,

a procedure must be applied for the safe disposal of waste material. It must comply with

all prevailing regulations and legislations of the country where the equipment is to be

used,

protective

clothing should

always

be

worn

in

compliance

with the

material

manufacturers' recommendations,

depending on the application and chemical safety instructions, safety glasses, hearing

protective earplug, gloves, foot wear, protective masks and possible breathing

equipment should be worn to comply with the regulations (Refer to chapter "Safety

equipment of KREMLIN selection guide).