KREMLIN REXSON

- 1 -

N° : 578.143.110-UK-1208

The extrusion quality depends directly on the shape of the tip. It is recommended to replace it regularly to

get a constant fan pattern.

A prematury wearing deformes the tip and makes it bigger, thus resulting in higher output.

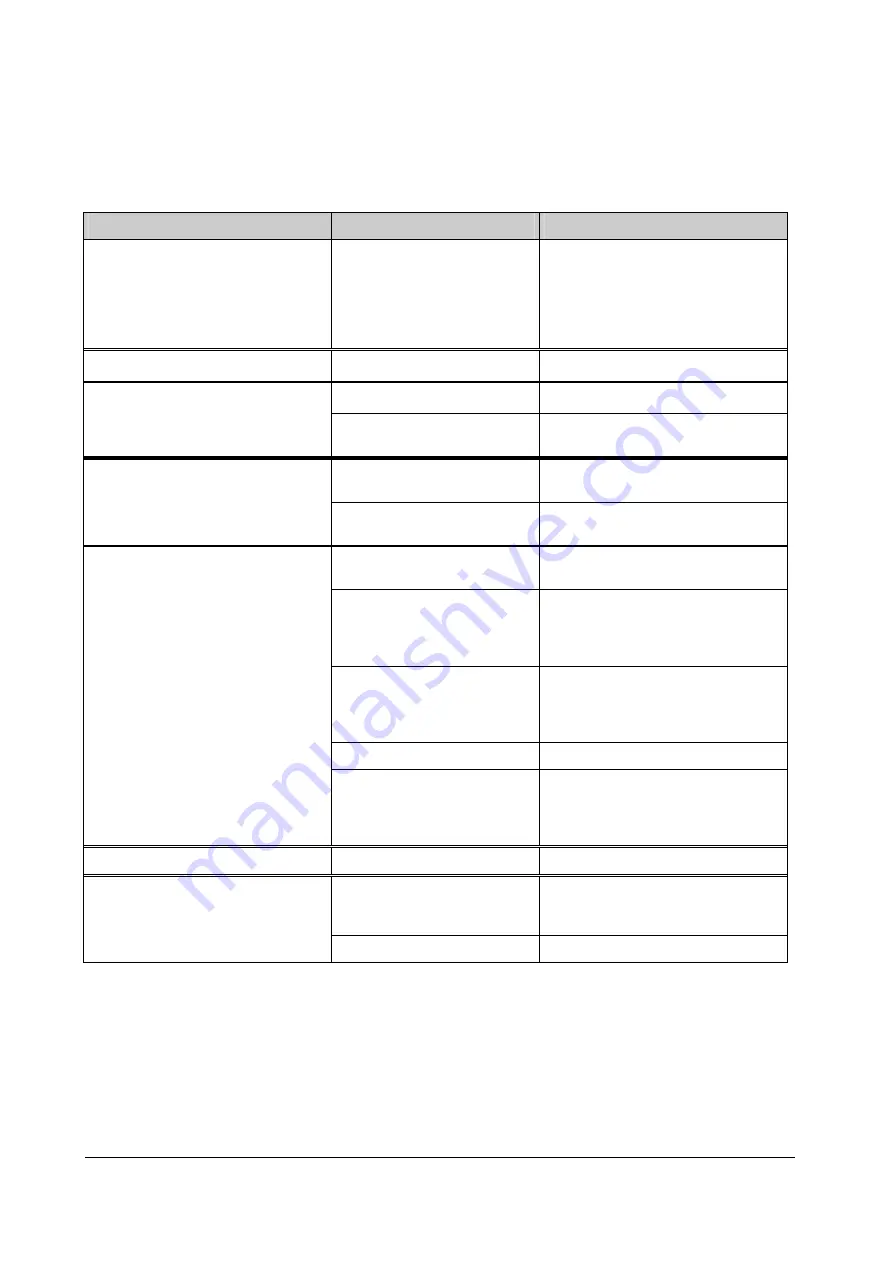

TROUBLE

CAUSE

SOLUTION

Material is no longer coming out of

the gun

Clogged nozzle

Check

material

supply

circuit.

Cut the pressure on the pump

Remove and clean the nozzle.

Depressurise the hoses.

Deformed bead

Nozzle worn

Change it.

Extrusion of intermittent material

Lack of material

Check the material supply.

Loose elements

Tighten

the

different

elements

(nozzle, fittings, etc.)

Fluid leak

Seals missing or damaged

Check

the

seals,

replace

if

necessary.

Loose elements

Tighten

the

different

elements

(nozzle, fittings, etc.).

Fluid leak in front of the gun

Dirt in the material

Trigger the gun 3 or 4 times or

clean the seat.

Bad tightness between the

ball and its seat

Clean the seat or replace the

needle assembly (model 250 bar

/ 3627 psi) / the ball (model

500 bar / 7251.5 psi) and the seat.

Ball or ball seat misplaced

Replace

the

needle

assembly

(model 250 bar / 3627 psi) / the ball

(model 500 bar / 7251.5 psi) and

the ball seat*.

Ball or ball seat are dirty

Clean the ball and the ball seat*.

Worn ball or ball seat

Replace

the

needle

assembly

(model 250 bar / 3627 psi) / the ball

(model 500 bar / 7251.5 psi) or /

and the ball seat*.

Fluid leak around the needle

Worn fluid packing

Clean or replace it.

Fluid leak from the trigger end of

the gun

Loose retainer (model

500 bar / 7251.5 psi)

Take out the lever and tighten the

retainer

(model

500

bar

/ 7251.5 psi).

Worn fluid packing

Replace the fluid packing.

*When installing ball and ball seat, make sure that the seat is in line with the parts inside the gun.