KREMLIN

Page 4

Manual : 573.156.112

FLUID OUTPUT

Having selected the proper fluid and nozzle/needle assembly and the fluid pressure, it is possible to

further control the output by adjusting the travel of the needle (knurled knob located on the lower rear

section of the spray gun).

7. GUN HANDLING

When mounting the air cap on the gun, hold it vertically in order to correctly adjust the air cap before

screwing the air cap ring. Keep the gun perpendicular to the surface to be painted.

8. GUN CLEANING

Never use metal brushes files, points or clips for dismantling

SHORT BREAKS (LESS THAN 3 HOURS)

Remove the paint on the air cap, with a brush and solvent. Otherwise leave the equipment as it is.

Removing the paint will prevent the drying and clogging of the holes.

LONG

BREAKS

Gun

: Unscrew the air cap.

Remove the needle and then remove the fluid nozzle with the wrench provided. Soak the needle, air

cap, fluid nozzle in solvent, clean the internal part of the gun, carefully brush the threated parts.

Never soak the gun in solvent

Paint cup

: If you want to keep the paint in the cup, put a cover on it to prevent its drying. If not, empty

out the paint and replace it with solvent. Clean the inside and outside part of the cup with a brush

soaked in solvent.

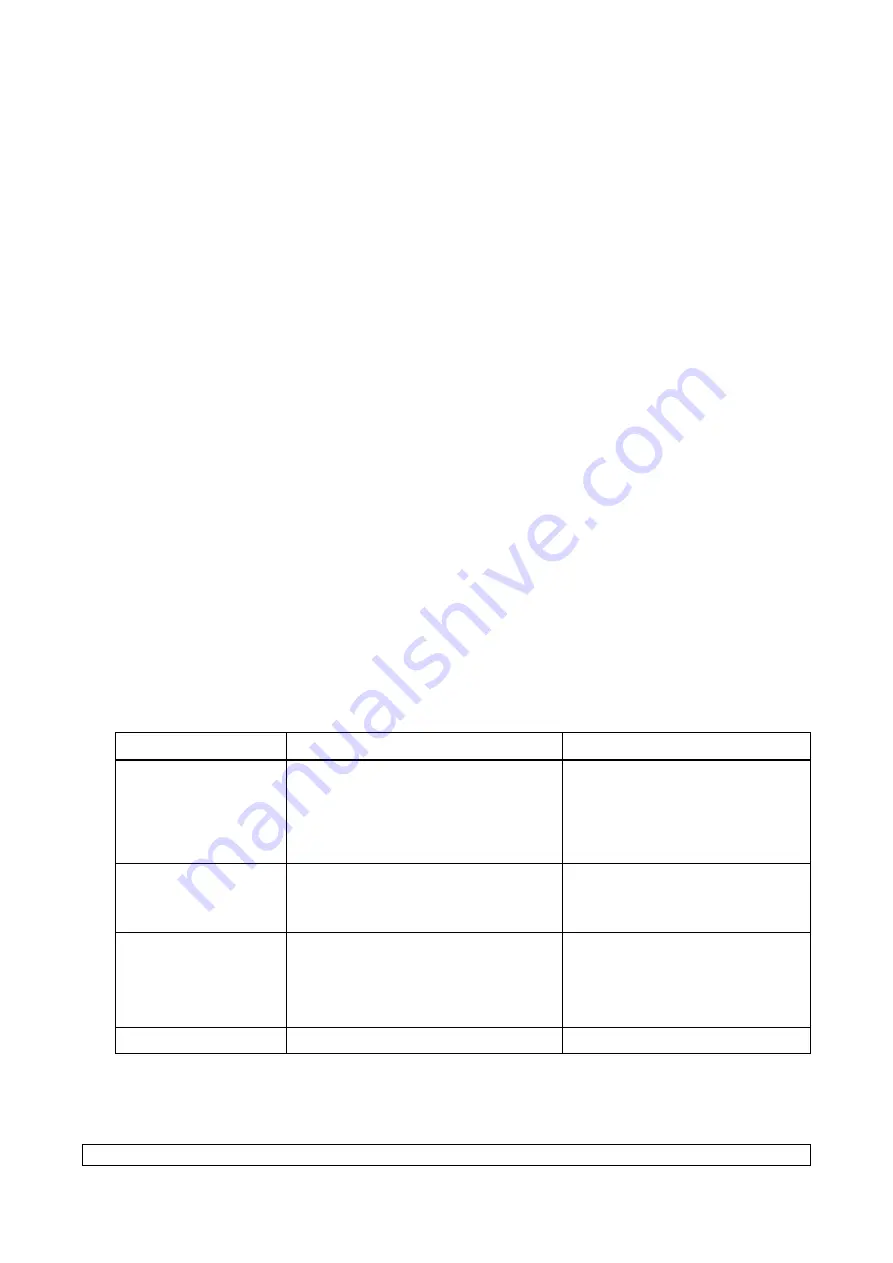

9. TROUBLESHOOTING CHART - WHAT TO DO

TROUBLE CAUSE

SOLUTION

Spray fan is not

uniform.

Air holes in air cap are partially

blocked.

Improper ratio between Air pressure /

Fluid flow rate.

Nozzle is damaged.

Clean air cap.

Turn the fan air control and adjust

fluid flow rate.

Change it.

Intermittant spray

pattern.

Paint cup (or pressure tank) is empty.

Nozzle not correctly tightened.

Cup cover air hole blocked.

Fill it up.

Tighten nozzle.

Clean it.

Paint leak.

Dirt in the paint.

Needle is worn out.

Packing is worn out.

Operate 3 or 4 times the trigger

and release it.

Replace it.

Replace it.

Air valve leak.

Defective valve.

Replace it.