3

Inspection and Maintenance

3.1 Maintenance

Owing to the modern Pneumatic Technique, the cutter is maintenance-free.

If any defects should appear, please contact the manufacturer.

Lubricate blade head friction

areas every 500 cuts. Dip it in

lubricating oil and pull the trigger

several times keeping the blades

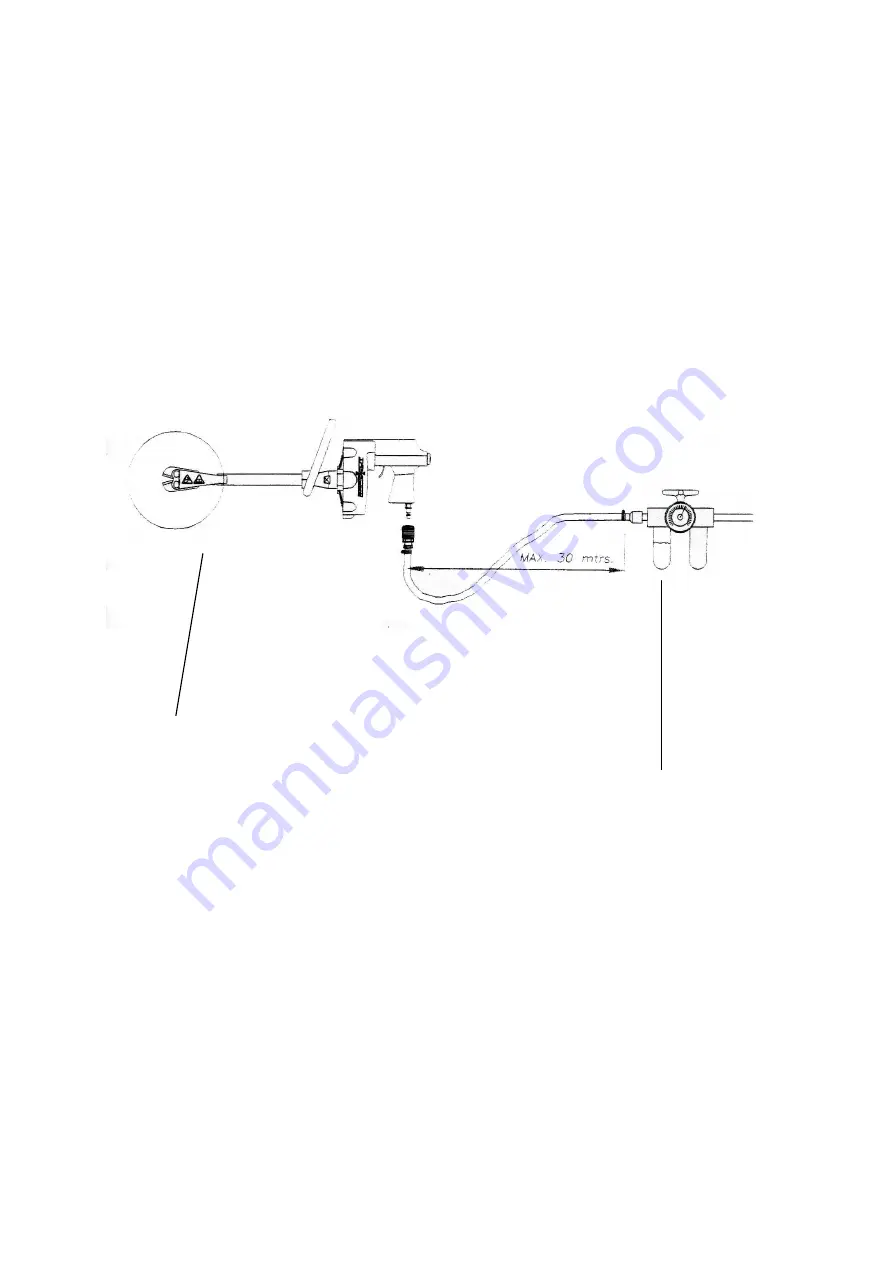

By installing a device to remove

in the oil. THIS WAY YOU WILL

water, adjust pressure and

OBTAIN OPTIMUM PERFORMANCE

lubricate air, the useful life of the

OF THE BLADES DURING THEIR

body and guides of the cutter is

USEFUL LIFE.

remarkably lengthened.

7

Summary of Contents for KRC 8

Page 1: ...PNEUMATIC REBAR CUTTER MODEL KRC 8 KRC 8 L INSTRUCTION MANUAL ...

Page 12: ......

Page 13: ...KRC 8 8 L ...