8

English

Before any work on the machine itself, pull the

mains plug!

Operate the machine only with the auxiliary han-

dle 12. Place the auxiliary handle on the clamping

collar and tighten with the clamping screw.

Damaged mains cables must not be used. They must

be replaced without delay by an authorised servicing

agent (heavy rubber sheathed code designation

H 07 RN-F).

Check before putting into operation that the mains

voltage agrees with the voltage specified on the

nameplate of the machine.

SWITCHING ON/OFF

Press or release the on/off switch 8.

The on/off switch can be locked on with the locking

button 7. To release, briefly press and release the on/

off switch 8.

DRILLING - IMPACT DRILLING

For drilling, place the selector 10 in the

position.

For impact drilling, set to

.

The switch-over can best be performed at a standstill.

Only after the on/off switch 8 is actuated and the

machine starts does the gear box shift to the selected

mode.

Note: Left rotation when impact drilling damages the

drill. Switch off the impact mechanism for diamond

crown drilling or for mixing work.

When hammer drilling, use exclusively drills with

hard metal inserts and SDS-Plus shafts. The use of

commercially available masonry drills with cylindrical

shafts by means of the adapter 13 and the normal drill

chuck in conjunction with the pneumatic impact mech-

anism is not possible.

Operate the rotational direction

switch 6 only when the machine is

at a standstill!

Take hold of the rotational direction

switch 6 on both sides.

Right rotation: Set the rotational direction switch 6

to “R”.

Left rotation:

Set the rotational direction switch 6

to “L”.

Important: Press the rotational direction switch 6 in

each case to the stop on the housing, i. e. until it can

be felt to engage.

If the rotational direction switch 6 is set between the

positions “R” and “L”, the machine cannot be switched

on.

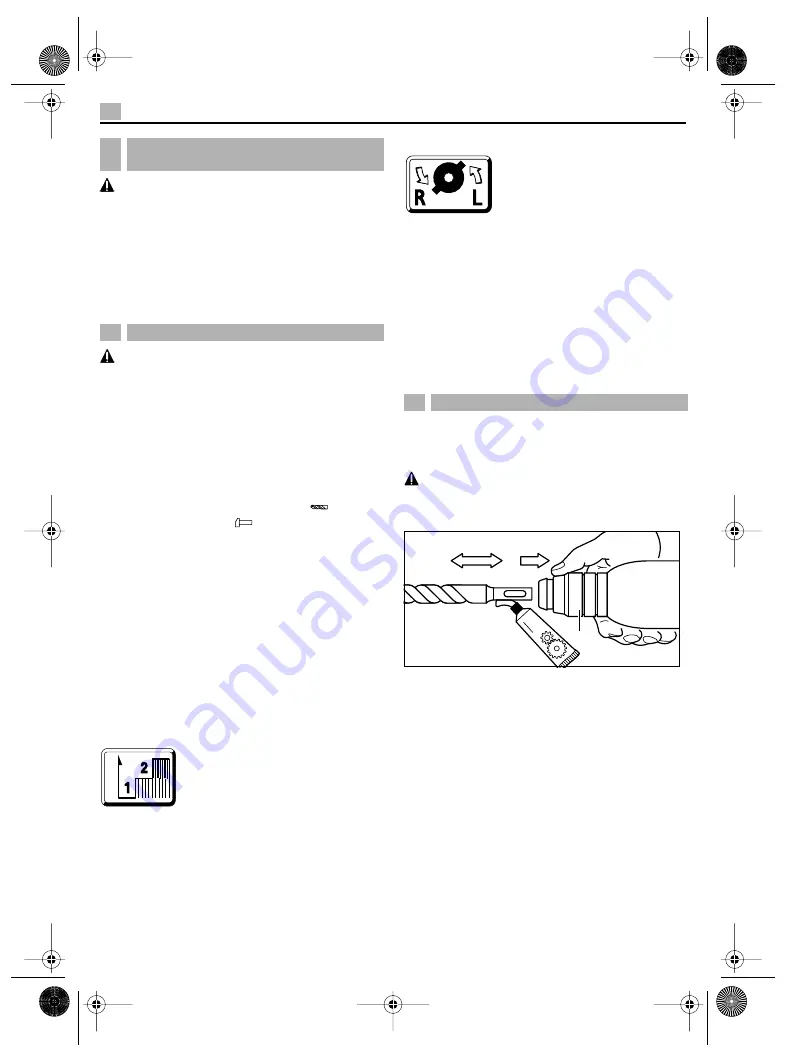

The tool holder 1 clamps the drilling tools without

using a tool key.

INSERTING TOOLS

Before any work on the machine itself, pull the

mains plug!

Clean and lightly grease the tool shaft.

Pull back the unlocking collar 3. Insert the tool while

turning into the tool holder until it latches. Release the

unlocking collar. Check whether the tool is firmly

seated.

Take care that the dust protection cap 2 is not dam-

aged.

Replace damaged dust protection caps!

REMOVING TOOLS

Slide the unlocking collar 3 to the rear and pull out the

tool.

5

Mounting the Auxiliary Handle,

Powersupply Cord

6

Putting into Operation

7

Inserting/Removing Tools

Fett

3

PH 500 - GB Seite 8 Montag, 17. September 2001 1:20 13

SPEED CONTROL

With the

O

n/

O

ff switch 8,

two speed

steps can be selected.

For hole starting, press the On/Off

switch 8

lightly (hole starting step).

For full drilling performance, press

in the On/Off switch

8

completely.

SPEED

ROTATIONAL DIRECTION SWITCHING