9

EN

TROUBLE SHOOTING

The following table gives checks and actions that you can perform if your machine does not operate correctly.

If these do not identify/solve the problem, contact Kress Customer Service.

I would add a comment here to again recommend that you apply grease to the shank of every drill bit used.

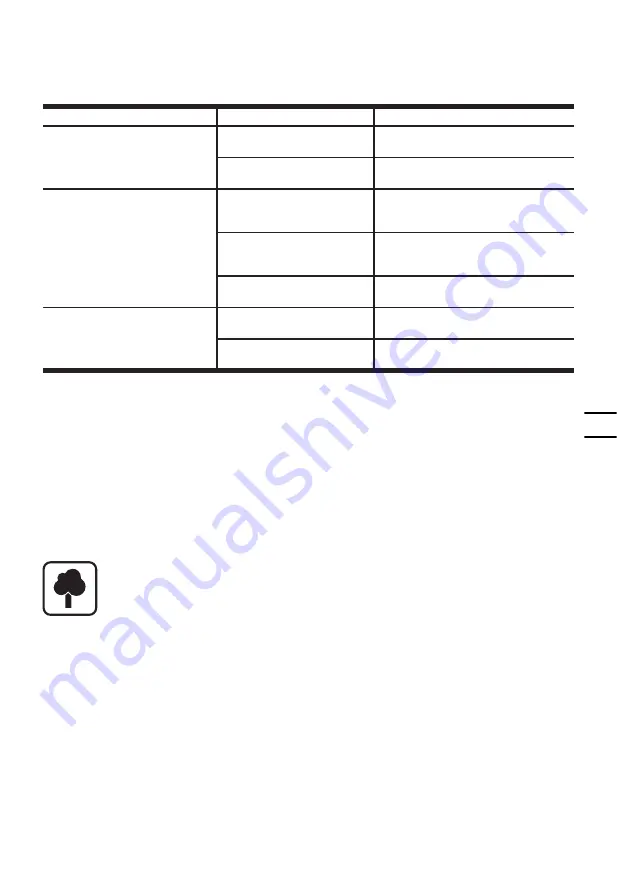

Symptom

Possible Cause

Possible Solution

Machine fails to operate

No power supply to machine

Turn power on

Use another socket

The brushes are worn out

Have a qualified person to check them,

and replace them if necessary

The power and hammer efficiency

of the machine is low.

Machine may be cold

Warm up the machine for 1-2 minutes

until it reaches a proper working

temperature

Your drill bit does not slide

freely in the chuck

Clean the dust and debris inside the

chuck; Grease the shank of the bit if

necessary.

There is no enough grease oil

in the gearbox

Have a qualified person to add some

grease oil (about 2 or 3 bottle caps)

Your drill bit will not fit into the

chuck easily

The chuck is dirty with dust

and debris.

Clean the dust and debris from inside

the chuck

The shank of the bit is

damaged or distorted

Change a new bit

MAINTENANCE

Remove the plug from the socket before carrying out any adjustment, servicing or maintenance.

There are no user serviceable parts in your power tool. Never use water or chemical cleaners to clean your power

tool. Wipe clean with a dry cloth. Always store your power tool in a dry place. Keep the motor ventilation slots clean.

Keep all working controls free of dust. Occasionally you may see sparks through the ventilation slots. This is normal

and will not damage your power tool.

If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified

persons in order to avoid a hazard.

Add approximately 10 grams of 1# lubricant (about 2-3 water bottle caps) to the gearbox every 100 operating hours.

ENVIRONMENTAL PROTECTION

Disposal

The machine, its accessories and packaging materials should be sorted for environmentally friendly

recycling.

The plastic components are labeled for categorized recycling

Summary of Contents for KU334

Page 1: ...Rotary Hammer EN P06 Перфоратор RU P10 KU334 ...

Page 2: ......

Page 3: ...1 2 3 4 5 6 7 ...

Page 4: ...A B1 B2 C D E F G1 1 1 2 2 ...

Page 5: ...F G1 G2 ...

Page 15: ......