6

OPERATION OF INDICATOR M10

36

BW25

www.krohne.com

10/2008 • 4000432301 MA BW25 R01 en

Device drivers for HART

™

tools, process control equipment (e.g. Siemens PDM or AMS)

PACTware

™

and HART

™

DTMs are available at the KROHNE Download Center.

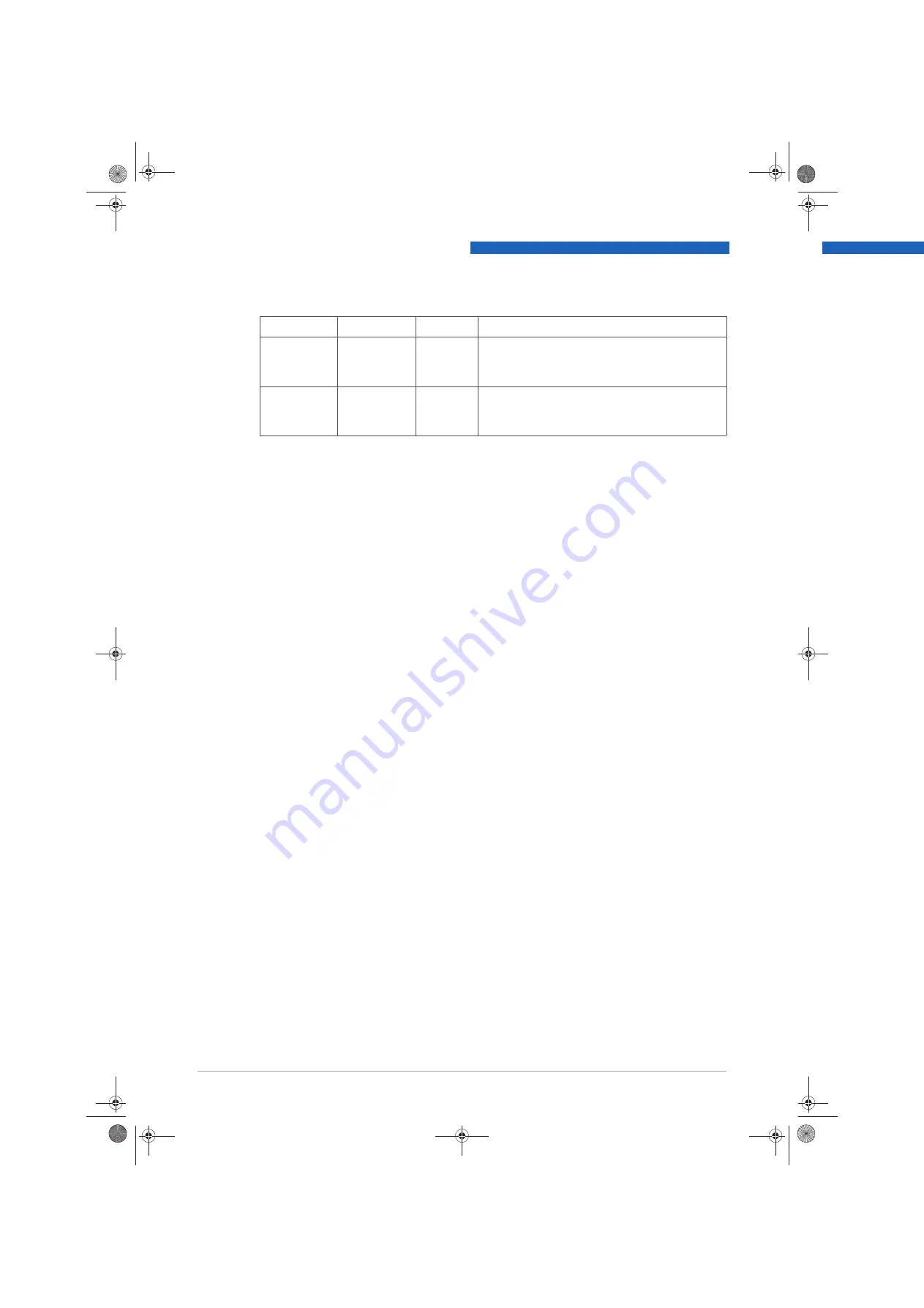

AO FIXED

The analog

output is set to

a fixed value.

Information

The analog output is fixed and does not reflect the

measured value. This is the case in Multidrop mode,

with analog output test/calibration using the menu or

HART

™

AO

SATURATED

Analog output

saturated

Information

The analog output is saturated at 20.4 or 22.0 mA

(depending on whether the alarm current is activated

or deactivated in menu item 3.12), and is no longer

coupled with the measured value.

Error Message

Description

Category

Remedy

MA_BW25_R01_en_PRT.book Page 36 Thursday, October 30, 2008 3:49 PM