DEVICE DESCRIPTION

2

13

DK37/M8 - H250/M8

www.krohne.com

11/2017 - 4002616802 - AD DK37 NEPSI Ex ia R02 en

The permitted ambient temperature range is indicated on the nameplate; depending on the

device version it is

T

amb

= -40...+65

°

C / -40...+149

°

F or T

amb

= -25...+65

°

C / -13...+149

°

F.

The minimum product temperature is -40

°

C / -40

°

F.

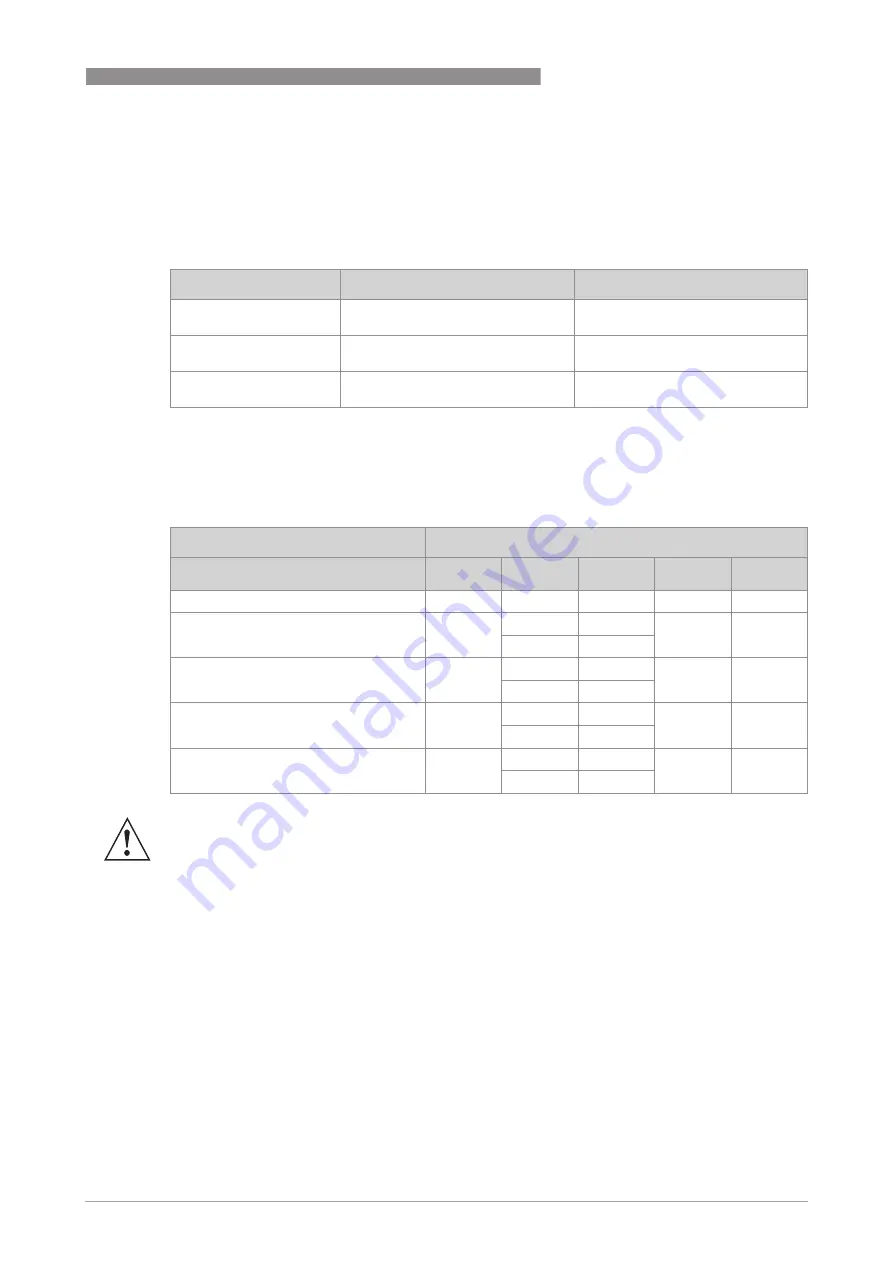

2.8 Electrical data

Built-in equipment for the variable area flowmeter may only be connected to separate

intrinsically safe circuits with the following maximum values:

Type

Electrical built-ins

Min. ambient temperature

H250/../M8EG

DK37/M8E/../..

Signal output 4...20 mA

-40

°

C / -40

°

F

H250/../M8MG

DK37/M8M/../..

SJ2-S1N

SC2-N0

-25

°

C / -13

°

F

H250/../M8MG

DK37/M8M/../..

I7S2002-N

SJ2-SN

-40

°

C / -40

°

F

Maximum values

Device version

U

i

[V]

I

i

[mA]

P

i

[mW]

C

i

[nF]

L

i

[

μ

H]

DK37/M8E/../.. or H250/../M8EG

30

120

1000

0

~ 0

DK37/M8M/../.. or H250/../M8MG

SC2-N0...

16

25

64

165

150

52

169

DK37/M8M/../.. or H250/../M8MG

SJ2-SN

16

25

64

45

100

52

169

DK37/M8M/../.. or H250/../M8MG

SJ2-S1N

16

25

64

75

100

52

169

DK37/M8M/../.. or H250/../M8MG

I7S2002-N

16

25

64

165

120

52

169

WARNING!

Also, when operating the variable area flowmeter outside of the hazardous area, the connection

must be made to an intrinsically safe circuit. When connecting to non-intrinsically safe circuits,

there is a risk of damage to the safety-defining components.