2

INSTALLATION

8

OPTIFLUX 7300

www.krohne.com

10/2020 - 4008325701 - QS OPTIFLUX 7300 R03 en

2.7 General requirements

2.7.1 Vibrations

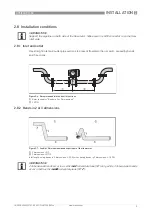

2.7.2 Magnetic field

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Signal converters installed in control cabinets require adequate cooling, e.g. by fan or heat

exchanger.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with EN/IEC 60068-2-64.

•

Avoid magnetic field! Keep at least 5 DN distance between electromagnetic flow sensor.

Figure 2-4: Avoid vibrations

Figure 2-5: Avoid magnetic fields