Handbook OPTIFLEX 1300 C

73 OPTIFLEX

1300

C

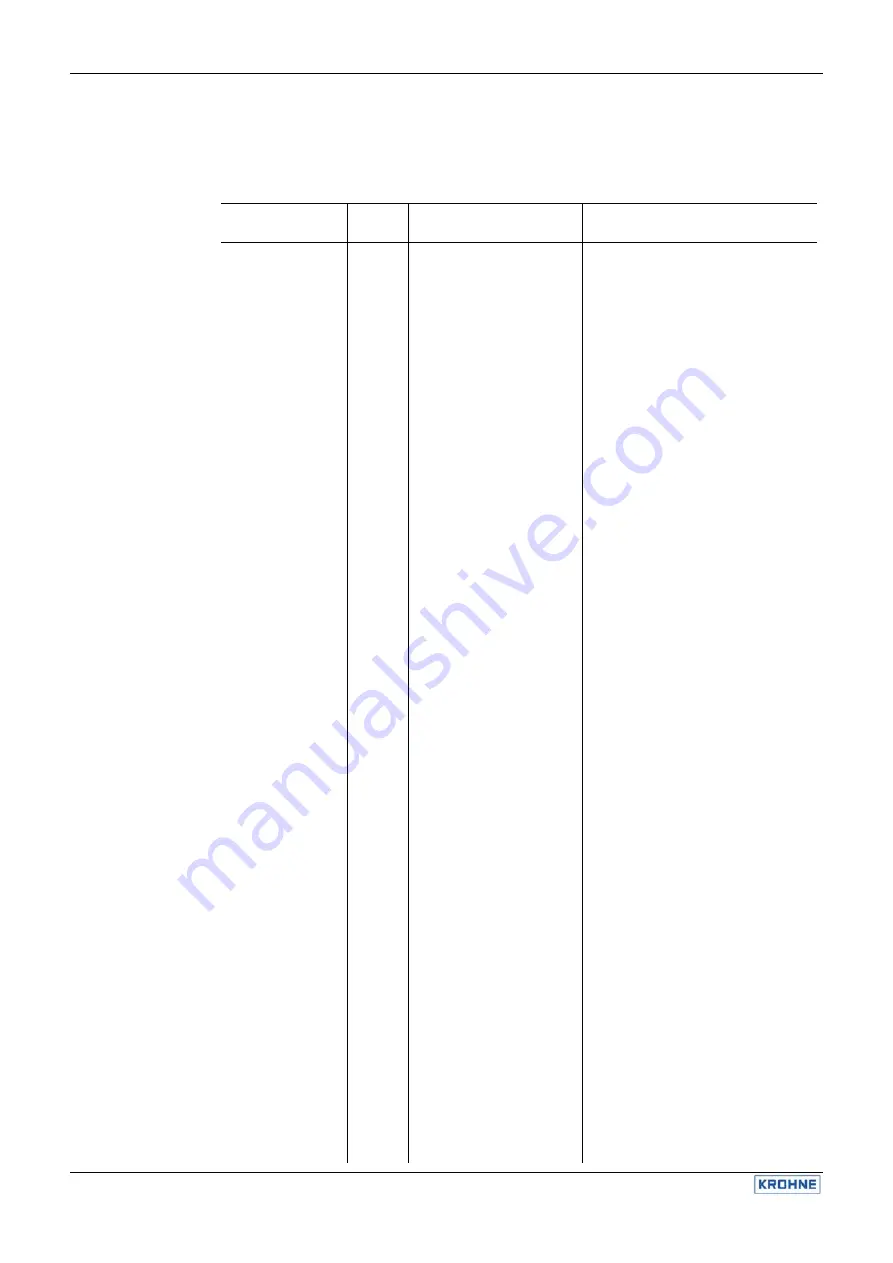

List of possible errors

The two types of errors are logged

1. Fatal (F): the measured value is not correct.

2. Warning (W): if the problem persists the measured value will no longer be correct.

Error Message

Type of

Error

Fault Action

Measurement

status

Level measurement

lost

W

The device can no longer find

the product surface

Check the tank contents using another

(visual?) method. If the tank is empty, in

other words below the probe end, then

fill the tank until product level is in the

measurement range. If the tank is full,

that is to say within the blocking

distance, then empty tank until the level

is back in the measuring range. If the

product was lost and the tank is neither

full nor empty, wait for the device to find

the level again.

Level measurement

high

F

The product level is in the

device's set blocking distance

or outside the measurement

range. The measurement is

either not correct or frozen.

Danger of overflow! Empty tank contents

to a safe level.

Level measurement

low

W

The product is below the

probe (and counterweight)

and/or outside the

measurement range. The

measurement is either not

correct or frozen.

Fill tank to at least the bottom of the

measuring range to continue

measurement.

Interface

measurement lost*

W

The device can no longer find

the interface

Check the tank contents using another

(visual?) method. If the interface is too

low (below the probe end), then fill the

tank with interface product until it is in

the set measurement range. If the

interface too high, that is to say within

the blocking distance, then empty tank

until the interface is back in the

measuring range. If interface is neither

high or low then an emulsion may exist.

Wait for the device to find the interface

again.

Interface

measurement high*

F

The interface is in the

device's set blocking distance

or outside the measurement

range. The measurement is

either not correct or frozen.

Danger of overflow! Empty tank contents

to a safe level.

Interface

measurement low*

W

The product is below the

probe (and counterweight)

and/or outside the

measurement range. The

measurement is either not

correct or frozen.

Fill tank to at least the bottom of the

measuring range to continue

measurement.

Layer measurement

low*

W

When the layer is less than

50 mm (2") or below the

probe end.

Fill tank with top product to at least 50

mm (2") or fill with bottom product at

least to at least the bottom of the

measuring range to continue

measurement.

Summary of Contents for optiplex 1300 c

Page 1: ......

Page 49: ...Handbook OPTIFLEX 1300 C 49 OPTIFLEX 1300 C 1 Volume measurement of liquids...

Page 50: ...Handbook OPTIFLEX 1300 C OPTIFLEX 1300 C 50 2 Volume measurement of solids...

Page 51: ...Handbook OPTIFLEX 1300 C 51 OPTIFLEX 1300 C 3 Mass measurement of liquids or solids...

Page 62: ...Handbook OPTIFLEX 1300 C OPTIFLEX 1300 C 62 Finding the advanced setup menu...

Page 95: ...Handbook OPTIFLEX 1300 C 95 OPTIFLEX 1300 C Note...