10

UFM 3030

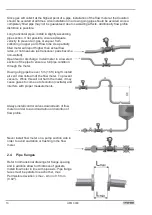

Since gas will collect at the highest point of a pipe, installation of the flow meter at that location

should be avoided at all times. Also installation in a down going pipe should be avoided since a

completely filled pipe may not be guaranteed due to cascading affects. Additionally flow profile

distortion is possible.

Long horizontal pipes: install in slightly ascending

pipe section. If not possible, ensure adequate

velocity to prevent air, gas or vapour from

collecting in upper part of flow tube As a partially

filled meter will report higher than actual flow

rates, or not measure (as transducer pairs become

non-wetted).

Open feed or discharge: Install meter in a lowered

section of the pipe to ensure a full pipe condition

through the meter.

Down going pipeline over 5 m (16 ft) length: install

air vent

downstream of the flow meter. To prevent

vacuum. While this will not harm the meter, it may

cause gases to come out of solution (cavitate) and

interfere with proper measurements.

Always install control valves downstream of flow

meter in order to avoid cavitation or distortion of

flow profile.

Never install flow meter on a pump suction side in

order to avoid cavitation or flashing in the flow

meter.

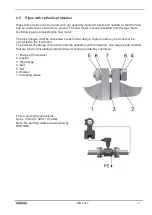

2.4 Pipe

flanges

Refer to dimensional drawings for flange spacing

and in addition allow for thickness of gaskets.

Install flow meter in line with pipe axis. Pipe flange

faces must be parallel to each other, max.

Permissible deviation: Lmax - Lmin

≤

0.5 mm

(0.02").