BCU 560, BCU 565 · Edition 02.16

18

1

2

3

46

45

65

66

67

68

49

50

51

17

18

37

38

13

14

15

N

L1

V1

V2

V3

max. 1 A;

24 V DC,

250 V AC

BCU 560..F2

3,15AT

µC

88

P70

P70

P73

P72

P72

c

c

ϑ

0 V

+24 V

41

42

24V

DC

HT

p

u

2

GZL

PZL

5 6

9

11 12

10

7

62 61

A

P72

P71

230V

mA

(P69 = 13)

52

53

54

55

56

COM

HI

LO

AUTO

P

I

Z

0,6 × I

N

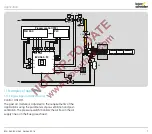

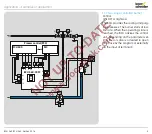

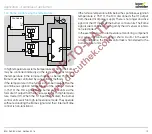

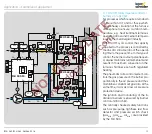

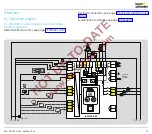

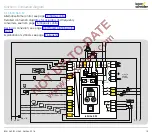

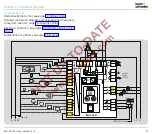

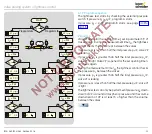

Function > Connection diagram

3 .1 .3 BCU 560 . .F2

Alternative flame control, see page 22 (Flame control).

Detailed connection diagrams for actuators and frequency

converters, see from page 78 (Capacity control)

Electrical connection, see page 106 (Project planning infor-