VAA · Edition 09.21

EN-3

➔

The inlet pressure p

u

and the outlet pres-

sure p

d

can be measured using the pressure

test points on both sides, see accessories.

p

d

p

u

➔

The seals in some gas compression fittings

are approved for temperatures of up to 70°C

(158°F). This temperature limit will not be ex-

ceeded if the flow through the pipe is at least

1 m

3

/h (35.31 SCFH) of gas and the maxi-

mum ambient temperature is 50°C (122°F).

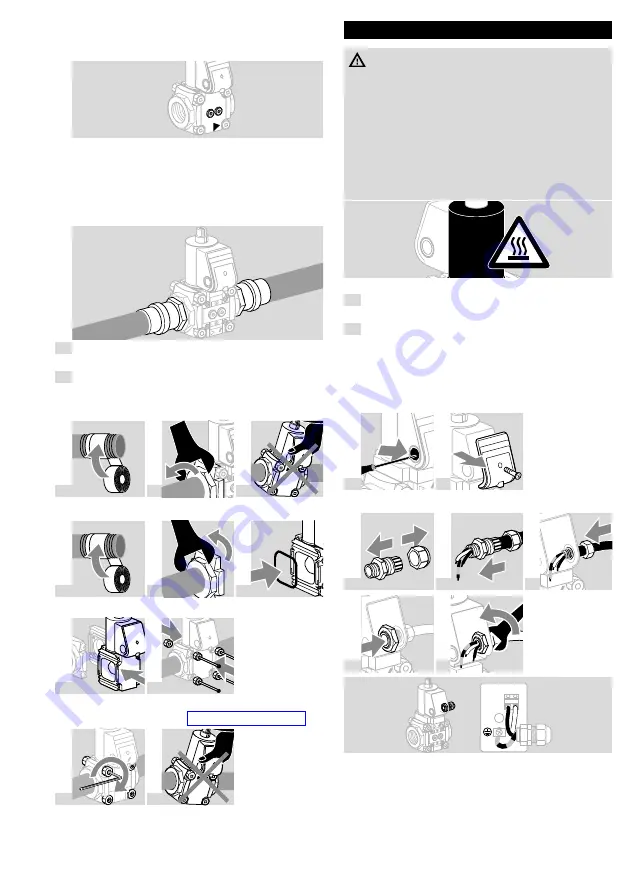

1

Remove the adhesive label or screw cap from the

inlet and outlet.

2

Obey the direction of flow as marked on the hous-

ing.

VAA with flanges

a

b

c

VAA without flanges

a

b

c

➔

O-ring (Fig.

c

) must be fitted.

d

e

➔

Note the recommended tightening torques for the

connection parts! See page 7 (Technical data)

f

g

WIRInG

WARnInG

Risk of injury!

Please observe the following to ensure that no

damage occurs:

– Electric shocks can be fatal! Before working on

possible live components, ensure the unit is

disconnected from the power supply.

– The solenoid actuator heats up during

operation. Surface temperature approx. 85°C

(approx. 185°F).

➔

Use temperature-resistant cable (> 80°C).

1

Disconnect the system from the electrical power

supply.

2

Shut off the air supply.

➔

Wiring to EN 60204-1.

➔

Push through and remove the knock-out in the

connection box before removing the cover. If the

M20 cable gland or plug is already fitted, it is not

necessary to remove the knock-out.

3

4

M20 cable gland

a

b

c

d

e

(+)

LV1

N

(-)