GB-3

D

GB

F

NL

I

E

Wiring

WARNING

Electric shocks can be fatal!

–

Before working on electrically live components,

ensure they are disconnected from the power

supply.

–

It must be possible to isolate the actuator from

the power supply. Provide a double pole switch.

▷

Install supply and signal lines separately.

▷

Conductors which have not been connected

(spare conductors) must be insulated at their

ends.

▷

Cables should be installed well away from high-

voltage lines of other devices.

▷

Observe EMC Directive for installation of signal

lines.

▷

If the power supply is susceptible to frequent

voltage peaks, we recommend that an electric

filter be used.

▷

Use temperature-resistant supply cables (≥ 90°C

and min. 1 – 1.5 mm² or AWG 14 – 18).

▷

Use cables with wire end ferrules.

▷

Cable cross-section: max. 2.5 mm².

▷

For information on assignment of the inputs

and outputs, see www.docuthek.com

1

Disconnect the system from the electrical power

supply.

Shut off the gas supply.

▷

Before opening the unit, the fitter should ground

himself.

3

4

5

6

Wire as shown on the connection diagram.

▷

Do not connect power supply and digital inputs

to different phases of a three-phase current sys-

tem.

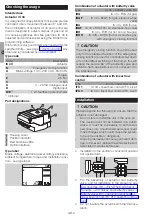

Connection diagram

N L1

L1 N

L1 N

100–230 V AC

50/60 Hz

COM NC NO COM NC NO

100–230 V AC

24 V DC

max. 230 V AC

max. 2 A

Power

DI 1

DI 2

RO 1

RO 2

IN Analog

4–20 mA

Potentiometer

max. 0,25 W

7

Assign inputs according to application.

▷

The load impedance of the 4 – 20 mA input can

be modified using the switch on the main circuit

board.

ON

1

50 Ω

ON

1

250 Ω

50 Ω

250 Ω

▷

Digital input DI 1/DI 2: in the case of 24 V DC,

check the polarity.

▷

Analogue input IN Analog: 4 – 20 mA, check

the polarity.

▷

For further information on the inputs, see

page 9 (Technical data).

8

Assign outputs according to application.

▷

Digital outputs RO 1 and RO 2: signalling con-

tacts designed as relay change-over contacts.

▷

For further information on the outputs, contact

current and relay contacts, see page 9 (Tech-

nical data).