GFK · Edition 05.19

EN-2

CHeCKInG tHe UsAGe

Gas filter GFK is used for filtration of the fuel gas and

combustion air supply to all gas consuming appliances.

This function is only guaranteed when used within the

specified limits – see page 3 (Technical data). Any

other use is considered as non-compliant.

type code

GFK

Gas filter

15 – 250

Nominal size

t

T-product

R

Rp internal thread

F

Flanged connection to ISO 7005

n

NPT internal thread

A

ANSI flange

Max. inlet pressure p

u max.

10

1 bar

40

4 bar (58 psig)

60

6 bar

-3

Screw plug at the inlet and outlet

-6

Pressure test point at the inlet and outlet

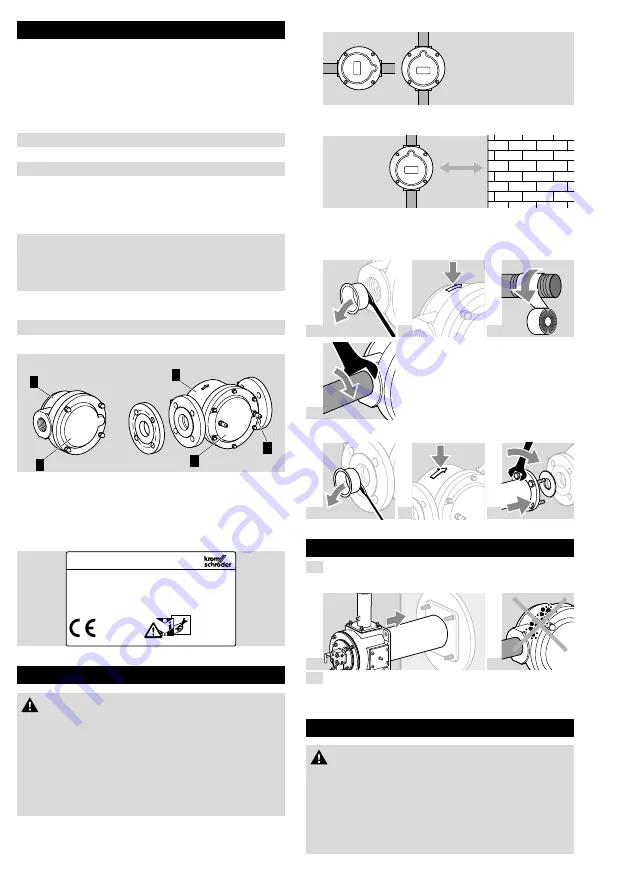

Part designations

GFK..F

GFK..R

1

1

3

2

2

1

Housing cover

2

Lower housing section

3

Pressure test point

type label

Max. inlet pressure: see type label.

D-49018 Osnabrück, Germany

GFK

p

u max

InstALLAtIon

CAUtIon

Incorrect installation

Please observe the following to ensure that the

GFK is not damaged during installation and

operation:

– Dropping the device can cause permanent

damage. In this event, replace the entire device

and associated modules before use.

➔

Installation position: as required, in hori-

zontal or vertical pipework – recom-

mended: housing cover to the side.

➔

The housing must not be in contact with ma-

sonry, minimum clearance 20 mm (0.79").

> 20 mm

➔

We recommend applying a protective coating when

installing in the open air.

GFK..R

1

2

3

4

GFK..F

1

2

3

tIGHtness test

1

To be able to check the tightness, shut off the

downstream pipeline close to the gas filter.

2

3

4

Tightness OK: open the pipeline.

➔

Pipeline leaking: replace the seal.

MAIntenAnCe

CAUtIon

In order to ensure smooth operation:

– clean or replace the filter pad of the GFK every

year, or every six months if operated with

biogas.

– When cleaning or replacing the filter pad, no dirt

may contaminate the clean gas circuit.