GFK · Edition 05.19

EN-3

➔

The filter pad should be changed at a pressure

gradient ≥ 20 mbar (8 "WC).

Pressure test points on the cover:

GFK 15 to 100:

inlet side: Rp 1/8 pressure test nipple,

outlet side: Rp 1/8 pressure test nipple.

GFK 125 to 250:

inlet side: Rp 1/8 plug,

outlet side: Rp 1/8 plug.

GFK 15T to 100T:

inlet side: Rp 1/8 plug,

outlet side: Rp 1/8 plug.

∆

p

max. = 20 mbar

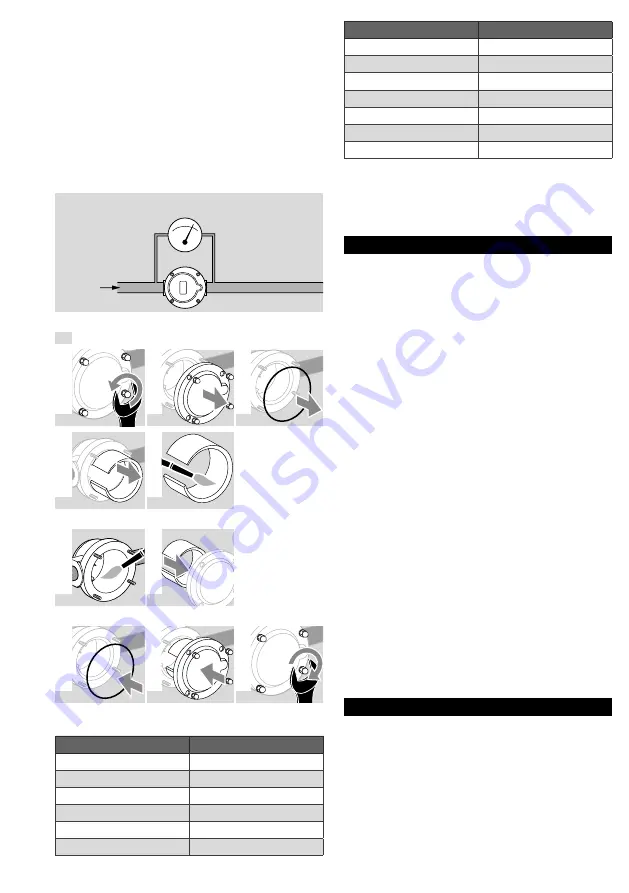

Cleaning or replacing the filter pad

1

Shut off the gas supply.

2

3

4

5

6

➔

Clean or replace the filter pad.

7

8

➔

Fit the filter pad into the groove in the cover.

9

10

11

➔

Tighten screws in a crosswise fashion and pay

attention to the torque, see table:

type

torque [nm]

GFK 15

5

GFK 20

5

GFK 25

8

GFK 32

8

GFK 40

8

GFK 50

8

type

torque [nm]

GFK 65

8

GFK 80

20

GFK 100

20

GFK 125

60

GFK 150

60

GFK 200

80

GFK 250

80

➔

When replacing the filter pad, the gas-filled space in

the GFK is opened. Therefore, check for tightness

once the filter pad has been reinstalled, see page

2 (Tightness test).

teCHnICAL DAtA

Gas type: natural gas, town gas, LPG (gaseous),

biogas and air.

Max. inlet pressure p

u

:

GFK 15 to 250: 1 bar,

GFK 15R to 65R, GFK 15TN to 100TN: 4 bar

(60 psig),

GFK 40F to 100F: 6 bar.

Ambient temperature: -15 to +80°C (5 to 176°F).

Continuous operation at high temperatures acceler-

ates the ageing of elastomer materials.

Version to DIn 3386

Housing

GFK 15 to 100 made from AlSi.

GFK 125 to 250 made from sheet steel.

GFK..R: Rp internal thread connection to ISO 7-1.

GFK..F: flanged connection to ISO 7005, PN 16.

GFK..N: NPT internal thread.

GFK..A: ANSI 150 flanged connection.

Filter pad: polypropylene fleece (standard 50 μm).

Pressure test points on the cover

GFK 15 to 100:

inlet side: Rp 1/8 pressure test nipple,

outlet side: Rp 1/8 pressure test nipple.

GFK 125 to 250:

inlet side: Rp 1/8 plug,

outlet side: Rp 1/8 plug.

GFK 15T to 100T:

inlet side: Rp 1/8 plug,

outlet side: Rp 1/8 plug.

DesIGneD LIFetIMe

This information on the designed lifetime is based on

using the product in accordance with these operat-

ing instructions. Once the designed lifetime has been

reached, safety-relevant products must be replaced.

Designed lifetime (based on date of manufacture) in

accordance with EN 13611 for GFK: 10 years.

You can find further explanations in the applicable

rules and regulations and on the afecor website (www.

afecor.org).