FCU 500, FCU 505 · Edition 02.17

128

Project planning information

With this circuit design, the function “Contactor feed-

back” at terminal 68 must be activated by setting pa-

rameter 73 to 1.

Before sending the pick-up signal to the contactors via

terminal 57, the FCU checks whether there is a signal at

the check signal input (terminal 68). If there is a signal,

the FCU issues the safety enable signal via terminal 57

to the connected burner control units. The contact

change is checked by the FCU, depending on the out-

put signal of terminal 57 (safety interlocks). If the FCU

detects a malfunction, a fault lock-out will occur with

fault message 37.

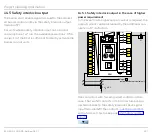

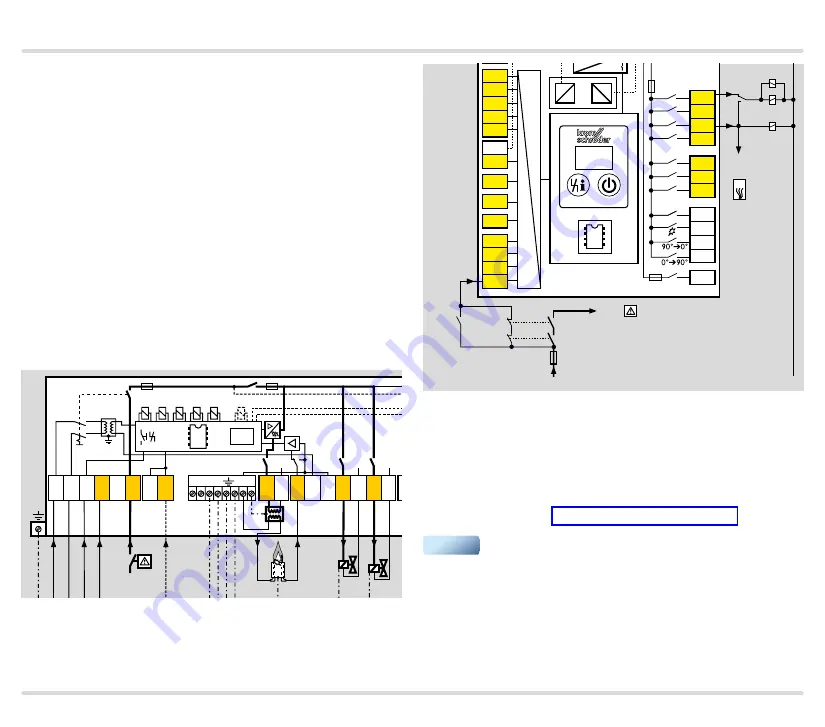

14 .5 .2 BCU with power supply for valves and ignition

transformer via safety interlocks

PE

s

s1

88

c1

F1

230V~

v1

c2

v2

max. 2 A,

253 V

V1 V2

C

N

S

µC

L

l

30 31 32 33 34 35 36 37 38 50 51

l

F3

40 41 42 43 44 45 46 47

1 2

5

6

11

9 10

12 13 14 15

18 19 20

26 27

22

8

7

PE

Z

I

V1

V2

P

L1 (L1)

N (L2)

DI

Test

L1

BCU 460

N1

N1

N1

N1

O

I

ϑ

3 4

16 17

n

max. 2 A,

253 V

A

23

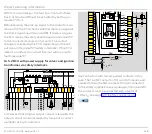

In the event that a higher output current is required, the

output current can be increased by means of a contact

multiplier using 3 contactors.

K3

k3

K1

k1

k1

k3

k2

k2

L1

1

2

3

46

47

48

49

50

4

67

44

52

45

51

65

66

68

41

42

16

17

18

57

13

14

15

53

54

55

56

58

62 61

5 6 7 8

11 12

STW/

STB

N

+24 V

L1

FCU

+ - + -

5AT

3,15AT

µC

24V

DC

88

K2

Input BCU

terminal 5

Input BCU

terminal 22

P

F = I

N

× 0.6

Use contactors with forced-guided contacts in this

case. The two NC contacts of K1 and K2 in series and

parallel to them the NO contact of K3 are connected

to the safety interlock check signal input (terminal 68).

The contacts must be protected with a factor of

≤ 0.6 x I

N

, see page 122 (Safety current inputs).

▼