FCU 500, FCU 505 · Edition 02.17

146

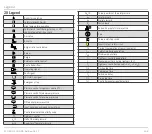

Glossary

21 .4 Timeout

For some process faults, a timeout phase elapses be-

fore the FCU reacts to the fault. The phase starts as

soon as the FCU detects the process fault and ends

after 0 to 250 s. A safety shut-down or fault lock-out

is then performed. If the process fault ends during the

timeout phase, the process continues as before.

21 .5 Lifting

After positioning the actuator IC 20, the FCU checks by

means of brief lifting whether its feedback input (termi-

nal 52) has been activated by the correct output signal

from the actuator. The signal of the relevant control

output (ignition, OPEN, CLOSE) is switched off briefly

for this purpose. While the signal is switched off, the

FCU may not detect a signal at the feedback input.

21 .6 Diagnostic coverage DC

Measure of the effectiveness of diagnostics, which may

be determined as the ratio between the failure rate of

detected dangerous failures and the failure rate of total

dangerous failures

NOTE: Diagnostic coverage can exist for the whole or

parts of a safety-related system. For example, diagnos-

tic coverage could exist for sensors and/or logic system

and/or final elements. Unit: %.

from EN ISO 13849-1:2008

21 .7 Operating mode

EN 61508 describes two modes of operation for safety

functions. These are low demand mode and high de-

mand or continuous mode.

In low demand mode, the frequency of demands for op-

eration made on a safety-related system is not greater

than one per year and is not greater than twice the

proof-test frequency. In high demand mode or continu-

ous mode, the frequency of demands for operation

made on a safety-related system is greater than one per

year or greater than twice the proof-test frequency.

See also EN 61508-4