FCU 500, FCU 505 · Edition 02.17

29

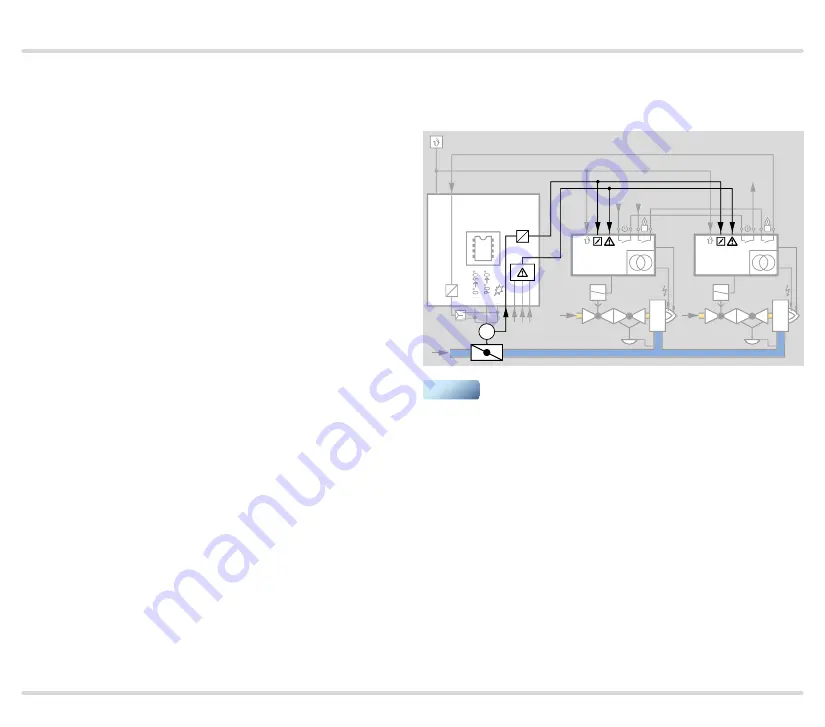

Air control

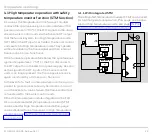

5 .2 Capacity control

As soon as a start-up signal has been received by the

FCU..F1/F2 (terminal 1), the fan of an FCU 500..F1/F2

is started via terminal 58 after the switch-on delay time

has elapsed. The air volume for pre-purge is requested

via the outputs for central capacity control (terminals

53 to 56). Air flow monitoring (terminal 48) starts. The

pre-purge time starts if there is adequate air flow.

After the elapse of the pre-purge time, the air volume

for ignition is requested. After the program has ended

(limits during start-up, pre-purge and also tightness

test for FCU..C1), the gas enable signal is issued via the

valve outputs V1 (terminal 13) and V2 (terminal 14) and

the burner start enable signal is issued to the burner

control units via the “safety interlock” output (termi-

nal 57).

The correct air volume for ignition (start fuel flow rate)

must be available for each burner start, restart or start-

up attempt. To this end, the FCU sends the burner start

enable signal to the BCUs via the “LDS (limits during

start-up)” output.

A corresponding circuit design between the FCU and

the BCUs ensures that the burners can only start if the

safety interlocks and the LDS output are active.

BCU

V1

BCU

V1

FCU 500..F1

µC

54 55

53

1

67

(BCU..F0)

+24V

L1

4

M

16

57

M

16

57

▼