FCU 500, FCU 505 · Edition 02.17

91

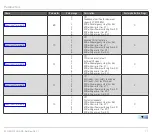

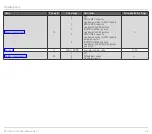

Parameters

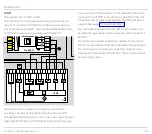

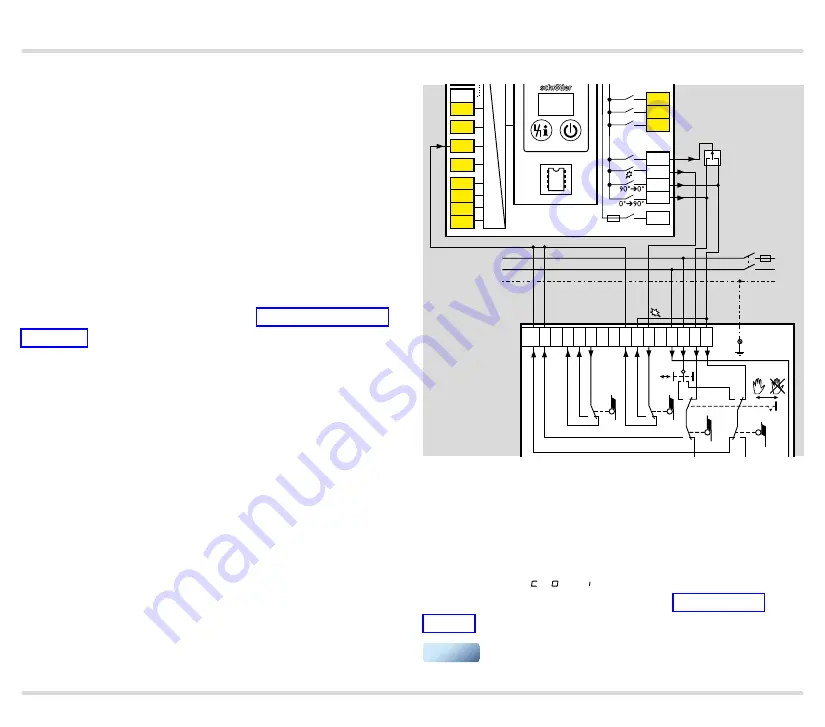

12 .4 .9 Capacity control

Parameter 40

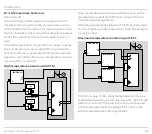

FCU..F1 and FCU..F2 are fitted with an interface for

connecting air actuators.

They activate a control element or frequency converter

via the outputs for capacity control (terminals 53 to 56)

for purging, cooling or starting the burners. The air ac-

tuator moves to the required position for the relevant

operating situation.

Using parameter 40, you can set which actuator is used

for capacity control.

Capacity control via bus, see page 103 (Capacity con-

trol (bus)).

Parameter 40 = 0: OFF; no capacity control (no air ac-

tuator)

Parameter 40 = 1: with IC 20

The interface is configured to the requirements of ac-

tuators IC 20, IC 20..E, IC 50 or IC 50..E.

Alternatively, comparable three-point step actuators

may be used.

IC 20

1

2

3

46

47

48

49

50

4

67

44

52

45

51

65

66

68

41

42

16

17

18

57

13

14

15

53

54

55

56

58

62 61

5 6 7 8

11 12

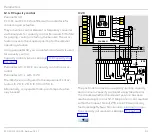

FCU 500..F1

5AT

3,15AT

µC

24V

DC

88

PE

L1

N

3PS

3 2 1

16

6

7

4

8

12 11

15

13

S3

S4

S11

S10

0°

90°

M

IC 20

PE

S1

S2

90°

➔

0°

0°

➔

90°

The positions for maximum capacity, ignition capacity

and minimum capacity can be set using the actuator.

It is checked whether the relevant position has been

reached using terminal 52. If the position is not reached

within the timeout time of 255 s, the FCU will display

fault message

A

,

A

or

A

(minimum, maximum or igni-

tion capacity not reached), see page 70 (Fault sig-

nalling).

▼