FCU 500, FCU 505 · Edition 02.17

129

Project planning information

Before sending the pick-up signal to the contactors K1

and K2 via terminal 57, the FCU checks whether there is

a signal at the check signal input (terminal 68). If there

is a signal, the FCU issues the safety enable signal via

terminal 57 to the connected burner control units. The

contact change is checked by the FCU, depending on

the output signal of terminal 57 (safety interlocks). If

the FCU detects a malfunction, a fault lock-out will oc-

cur with fault message 37.

The function “Contactor feedback” can be activated by

setting parameter 73 to 1.

14 .6 Actuators

If actuators are used, the start gas rate of the burners

must be limited for SIL 3 applications in compliance

with the standard.

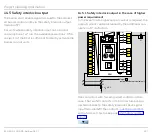

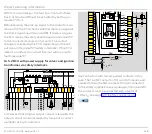

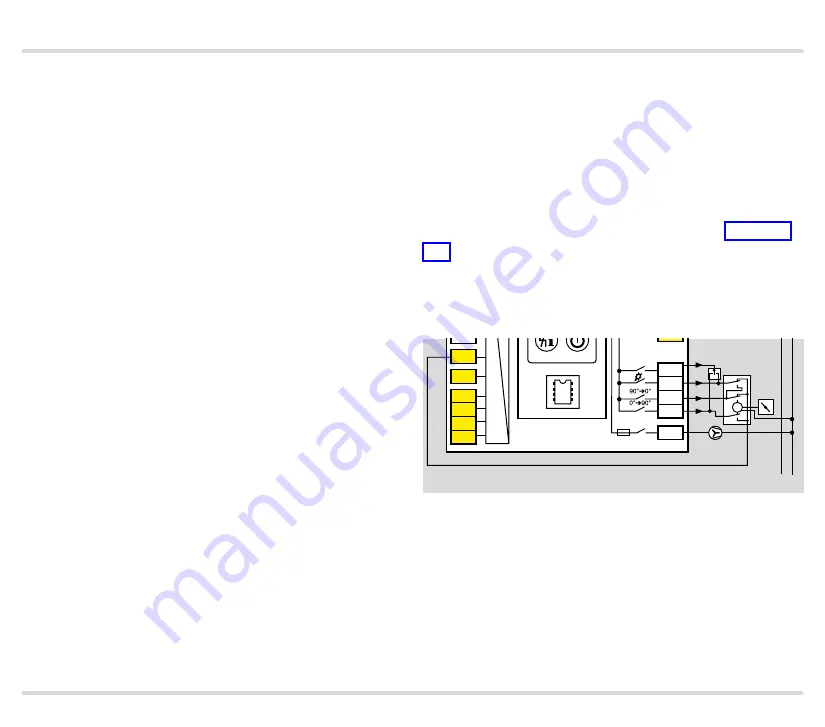

14 .6 .1 IC 20

The FCU..F1 checks the position to which the actuator

IC 20 has moved using terminal 52 (feedback) by lifting

the signal to terminal 53, 54 or 55, see page 146 (Lift-

ing).

To ensure this check is possible, FCU..F1 and actuator

IC 20 must be wired as shown in the connection dia-

gram.

1

2

34

6

47

48

49

50

4

67

44

52

45

51

65

66

68

41

42

16

17

18

57

13

14

15

53

54

55

56

58

62 61

5 6 7 8

11 12

N

0 V

FCU 500

+ - + -

5AT

3,15AT

µC

24V

DC

88

M

STW/

STB

14 .7 Air control

Starting the fan with the butterfly valve closed reduces

the start-up current of the fan motor.