FCU 500, FCU 505 · Edition 02.17

45

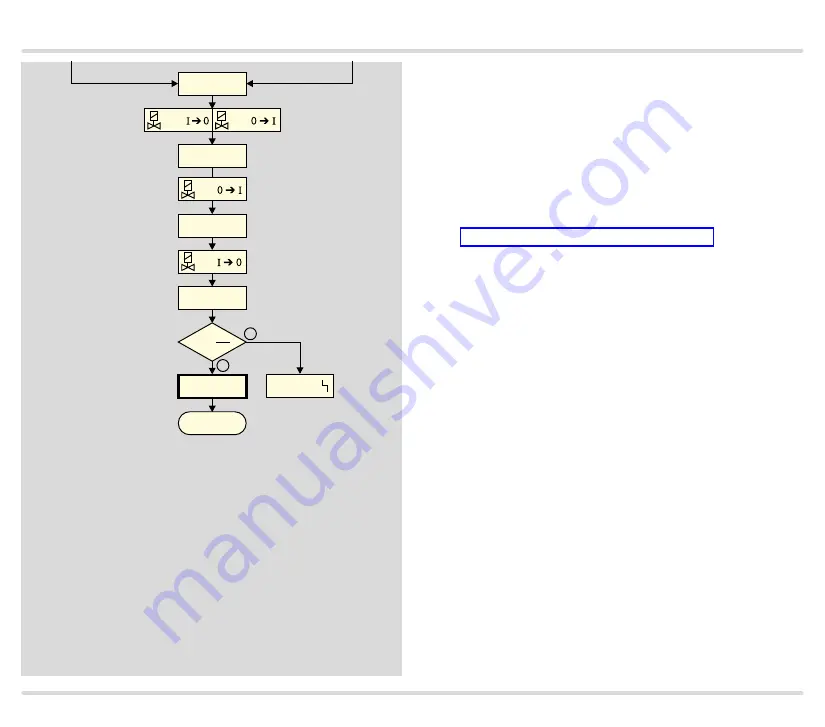

Valve proving system

tL = P59

tM = P56

+

–

tL = P59

tM = P56

pZ >

pu

2

+

–

V2

OK

pZ >

pu

2

V1

OK

V1

V2

OK

V1

V1

V1

OK

V2

V2

V2

V1

V2

pZ >

pu

2

+

–

pZ >

pu

2

+

–

tL = P59

tM = P56

V1

V1

tL = P59

tM = P56

V2

V2

pZ >

pu

2

+

–

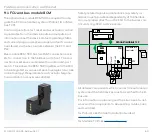

tL3 = P55

V3

Vp2 OK

Vp1

OK

pZ >

pu

2

+

–

tL = P59

tM = P57

V1

V2

V3

V1

Vp2

Program

A

Program

B

Program

A

Program

B

Vent V

p2

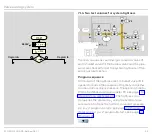

Test of valve 1

V

p1

Test of valve 2

V

p1

Test of valve V3

and

burner-side

valves

V

p1

+ V

p2

Wait for 1 s

END

START

Checking the first and second test volumes

(V

p1

+ V

p2

)

To check the test volume V

p2

, relief valve V3 is closed

and valve V2 is opened. The two test volumes V

p1

and

V

p2

are connected to each other. After a waiting time

of 1 s, valve V1 opens for the opening time t

L

set in

parameter 59. Valve V1 then closes and the measure-

ment time set in parameter 57 starts to elapse, see

page 110 (Measurement time V

). After the

measurement time has elapsed, the tightness control

checks pressure p

Z

. If p

Z

< p

u

/2, the test volume V

p2

is

leaking (relief valve V3, the burner valves or the pipe-

work are leaking). If p

Z

> p

u

/2, test volume V

p2

has been

successfully checked for tightness.

Valves V1, V2 and V3, the burner valves and the pipe-

work are tight.