II - 3

Safety

,

2.6

Hitched-up machines

1. Secure the machines against rolling away.

2. Keep to the maximum permitted supporting load

for the trailer coupling, towing device or hitch.

3. Make sure that there is sufficient movement for

the tow-bar trailer at the point of attachment.

2.7

Operation of the power take-

off shaft

1. Only articulated shafts which have been specified

by the manufacturer must be used.

2. Both the protective sleeve and protective funnel

for the articulated shaft and the protective device

for the power take-off shaft - both on the tractor

and on the machine - must be in place and must

be in proper working order.

3. Make sure that the tube covers stipulated for

articulated shafts are in the transport and working

position.

4. Only attach or detach articulated shafts with the

power take-off shaft switched off, the engine shut

down and the ignition key removed.

5. When using articulated shafts with an overload or

freewheel clutch which are not covered by the

protective devices on the tractor, the overload or

freewheel clutch must be mounted on the machine

side.

6. Always make sure that the articulated shaft is

correctly assembled and the safety device is in

proper order.

7. Secure the protective device for the articulated

shaft with a chain to prevent it from rotating with

the shaft.

8. Before switching on the tractor power take-off

shaft, make sure that the speed selected for the

shaft matches the speed permitted for the

machine.

9. Before switching on the power take-off shaft,

make sure that no one is inside the danger area of

the machine.

10. Never switch on the power take-off shaft with the

engine shut down.

11. When working with the power take-off shaft,

nobody must remain inside the area of the rotating

power take-off shaft or articulated shaft.

12. Always shut down the power take-off shaft when

the bend is unnecessarily too great.

13.

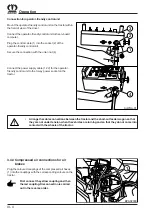

Caution

After shutting down the power take-off

shaft, there is a danger that parts which are

subject to inertia will continue running. Do not

approach the machine during this time. Work must

not be carried out on the machine until it is fully at

rest and parts subject to inertia have been

arrested by applying the parking brake.

14. Only carry out lubrication or adjustment work on

the machine or the articulated shaft with the power

take-off shaft switched off, the engine shut down

and the ignition key removed. Apply the parking

brake on parts subject to inertia.

15. When disconnected, stow the articulated shaft in

the mounting provided for this purpose.

16. After the articulated shaft has been disconnected,

place the protective cover on the power take-off

stub.

17. When damaged, remove immediately before

working with the machine.

2.8

Hydraulic unit

1. The hydraulic unit is under pressure.

2. When connecting hydraulic rams and motors,

make sure that the hydraulic hoses are connected

in the stipulated manner.

3. When connecting the hydraulic hoses to the

tractor hydraulic system, make sure that the

hydraulic systems on the tractor and the machine

are not under pressure.

4. The coupling sleeves and plug-in connectors of

the hydraulic function connections between the

tractor and the machine must be labelled to

prevent faulty operation. If the connections are

connected the wrong way round, operations (such

as lifting and lowering) will be reversed and there

will be a

risk of accident

5. Check hydraulic connections regularly and replace

if damaged or old. The replacement hoses must

comply with the technical requirements of the

machine manufacturer.

6. Because of the risk of injury, use suitable

accessories when looking for leaks.

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...