II - 4

Safety

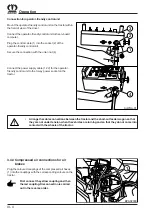

7. Liquids leaking under high pressure (such as

hydraulic oil) can penetrate the skin and cause

serous injury. In case of injury, immediately call a

doctor. Risk of infection.

8. Before working on the hydraulic unit, shut down

the machine, release the pressure in the unit and

shut down the engine.

2.9

Tyres

1. When working on the tyres, make sure that the

machine is securely shut down and secured

against rolling away (use wheel chocks).

2. Sufficient knowledge and the specified tools are

required to assemble wheels and tyres.

3. Repair work on the tyres and wheels must only be

carried out by specialists using the assembly tool

suitable for the purpose.

4. Check the air pressure regularly. Keep to the

specified air pressure.

2.10 Maintenance

1. When carrying out maintenance work, service

work or cleaning work or correcting faulty

operation, always make sure that the drive unit is

switched off and the engine is shut down and at

rest.

- Remove the ignition key. Apply the parking brake

on parts whihc are subject to inertia.

2. Regularly check if screws and nuts are firmly

seated and re-tighten if necessary.

3. When carrying out maintenance work on elevated

machines, always secure them using suitable

supporting elements.

4. If cutting instead of using work tools, use suitable

tools and gloves.

5.

Dispose of oil and grease filters in the proper

manner.

6. Always isolate equipment from the power supply

before working on the electrical system.

7. Protective devices subject to wear must be

checked regularly and replaced at the proper time.

8. When carrying out electric welding work on the

tractor and attached equipment, disconnect the

cable from the generator and the battery.

9. Spare parts must at least comply with the

technical requirements laid down by the equipment

manufacturer.

This is only guaranteed by using genuine KRONE

spare parts.

10. When storing gases, only use nitrogen for filling -

Risk of explosion.

2.11

Conversion by the customer

and making spare parts

Conversion of or changing the machine is only

permitted after consultation with the manufacturer. In

the interest of safety, only genuine parts and

accessories authorised by the manufacturer should be

used. No liability can be accepted for consequences

resulting from the use of other parts.

2.12

Non-permitted modes of

operation

The operational safety of the machine supplied is only

guaranteed if used properly in accordance with the

relevant section of the operating instructions - General

information. On no account must the limits quoted on

the data sheets be exceeded.

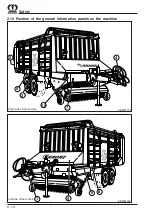

2.13

Safety instructions attached

to the machine

The safety instructions on the machine warn against

the remaining dangers on the machine. They consist of

warning symbols and work-safety symbols.

All safety instructions must be followed. Always

maintain safety instructions in a clean and easily

legible condition.

Request replacements for damaged or missing safety

instructions from the dealer and attach them to the

places designed for them.

Their position and meaning is described in the

following.

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...