III - 9

Operation

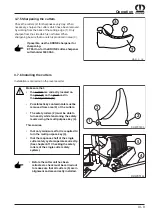

3.7.5 Sharpening the cutters

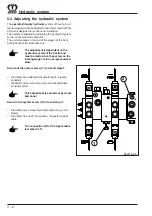

Check the cutters (2) for sharpness every day. When

necessary, sharpen the cutters which have been removed

by working from the back of the cutting edge (1). Only

sharpen from the side which is not fluted. When

sharpening be sure that no notch is produced in area (3).

If possible, use the KRONE sharpener for

sharpening.

ET Part no. for the KRONE cutter-sharpener

cutter holder 940 003-0.

KRS-1-06

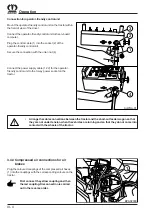

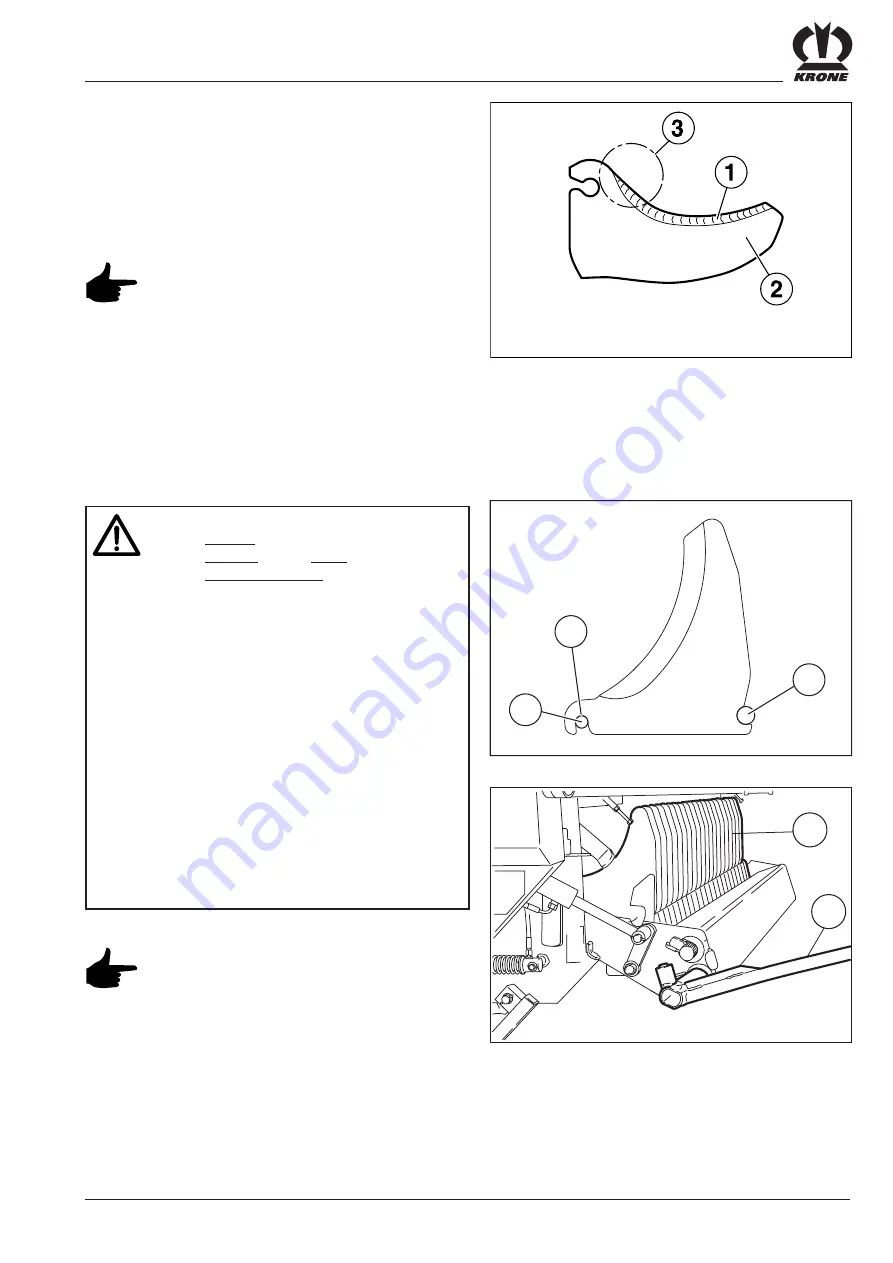

3.7.6 Installing the cutters

Installation is carried out in the reverse order.

Make sure that:

•

the cutters are correctly located on

the pins (1) on the pivot and in

the safety rollers (2) .

•

Possible sticky contaminants must be

removed from area (3) of the cutters.

•

The safety rollers (2) must be able to

turn easily while tensioning the safety

levers using the multi purpose key (4).

This ensures,

•

that only minimum effort is required to

turn the multi purpose key (4).

•

that the response shaft of the single

cutter safety system operates correctly.

(See chapter 6.11 Checking the safety

rollers of the single cutter safety

system).

•

Before the cutter unit has been

retracted, a check must be carried out

to make sure that all cutters (5) are in

alignment and are correctly installed.

4

5

KDW05144

KDW05145

2

1

3

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...