III - 11

Operation

3.8 Road travel

•

Do not exceed the permitted speed limit (see serial plate).

•

Riding on the feeder wagon is not permitted.

•

The roadworthiness of the feeder wagon must be checked before travelling on the public

highways, in particular the lights and tyres and whether the rear flap has been closed, the

articulated shaft lowered and whether the pick-up has been lifted out.

•

Travelling on public roads is only permissible with the ladder locked in folded up position.

•

Before starting, make sure that the view is completely clear on and around the tractor and

feeder wagon.

•

If driving on straight roads at speeds above 30 km/h with the wagon loaded, the steering axle

(special fitting) must be locked to increase stability while travelling.

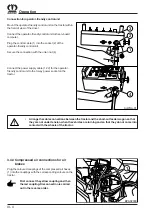

Before reversing,

first straighten the steerable wheels on

the rear axle and pressurise the arrest ram until the

steerable wheels are straightened.

It may also be necessary to drive a short distance

forwards or backwards in a straight line.

While driving backwards,

leave the pressure on the

hydraulic connection as it is.

While driving forwards,

switch the tractor valve for the

steering axle to „lower“ so that the wheels can adjust freely

when going round bends.

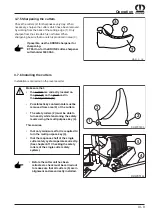

The steering axle must be locked when driving

forwards:

a) if the cornering stability of the non-steerable front axle is

no longer sufficient, for example:

• on a slope

• on un-made-up or unpaved ground

• when the first axle is relieved by operating the

articulated tow-bar

• while driving over a silo

• When travelling at speeds above 30 km/h on a straight

road with the wagon loaded, the steering axle must be

locked.

To do this, pressurise the arrest ram until the steerable

wheels straighten up. While driving forwards with the

steering axle locked, leave the pressure on the hydraulic

connection as it is.

An indicator lamp on the control box indicates that the

arrest ram is under pressure and the steering axle is

therefore locked.

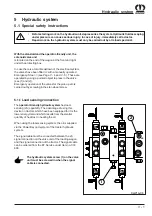

3.9 Handling the trailing axle (special

fitting)

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...