VI - 7

Maintenance

6.8

Checking and changing the oil

The oil level in the transmission must be checked regularly

before and after use.

An oil change should be carried out after the first period of

use (approx. 30-50 h). After this, change the oil once a

year. To do this, drain out the old oil from the transmission

and fill it with fresh gear oil SAE 90 APi-GL-4.

After an oil change, the old oil must be

disposed of in the proper manner.

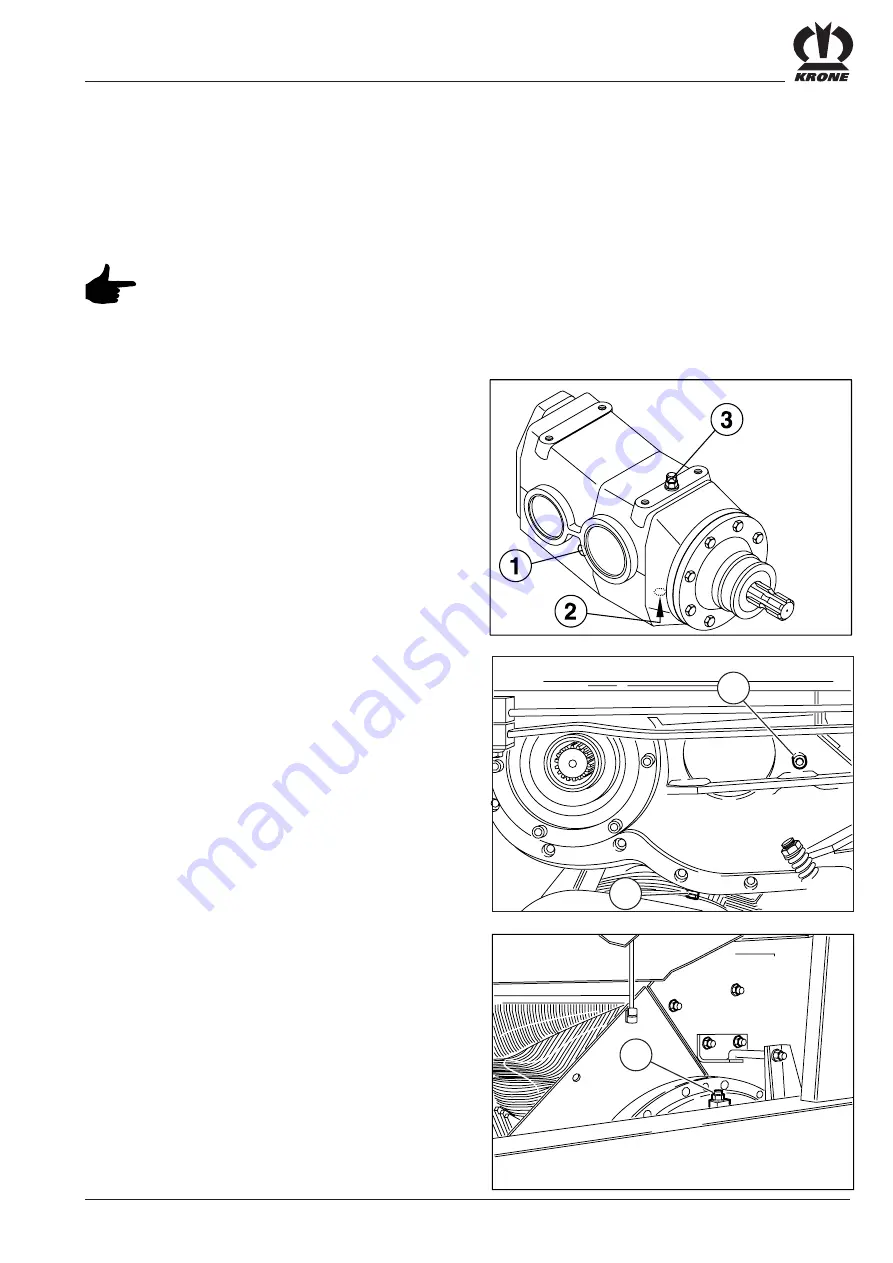

6.8.2 Conveyor drum

The oil inspection screw (1) for the conveyor drum is

located at the front right hand side of the loading wagon,

behind the protective cladding.

The oil level must be checked every 50 h.

KLW07100

1

3

KLW07090

2

KDW06333

Oil inspection:

•

Remove check screw (1)

•

Oil level up to bore hole (1)

•

If necessary, top up oil (2), fit check screw (1)

Oil change:

•

Unscrew the oil draining screw (3)

•

Collect the used oil in a suitable

collection vessel.

•

Fit oil draining screw (3)

•

Fill oil (2) (Oil level up to bore hole (1))

6.8.1 Main gearbox

Oil inspection:

•

Remove check screw (1)

•

Oil level up to bore hole (1)

•

If necessary, top up oil (SAE 90), fit

check screw (1)

Oil change:

•

Unscrew the oil draining screw (2)

•

Collect the used oil in a suitable

collection vessel.

•

Fit oil draining screw (2)

•

Fill oil (3) (Oil level up to bore hole (1))

•

Drive in oil level check screw (1) and breather (3).

Summary of Contents for 4XL-RGD

Page 4: ...Foreword ...

Page 10: ...I 4 General information ...

Page 15: ...II 5 Safety ...

Page 22: ...II 12 Safety ...

Page 64: ...VI 18 Maintenance ...

Page 66: ...VII 2 Overwintering ...

Page 68: ...VIII 2 Recommissioning ...

Page 70: ...IX 2 Faults causes and removal ...

Page 80: ...A 10 Appendix Operator friendlyoperation A2 Electrical circuit diagram ...

Page 81: ...A 11 Appendix ...

Page 82: ...A 12 Appendix ...

Page 83: ...A 13 Appendix ...