Maintenance

60

Pos: 29.34.19 /Ü berschriften/Ü berschriften 3/K- O/MMesserschr aubverschl uss @ 0\mod_1197270941296_78.docx @ 16578 @ 3 @ 1

10.12.1

Blade Screw Connection

Pos: 29.34.20 /BA/Wartung/M ähwer ke/M esserschr aub / M esserschnellverschluss/Beschr eibung M esser wechsel M esserschr aubverschl uss AM @ 70\mod_1305178894100_78.docx @ 635757 @ @ 1

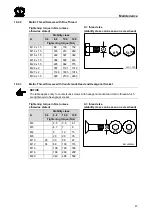

AM-4-032

2

3

4

1

5

4

1

2

5

Fig. 34

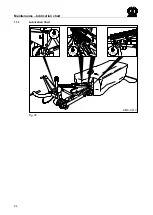

• Fold up the protective device

• Clean the area

• Remove damaged or worn blades

• To fit a blade (5), insert it between the wear plate (2) and the cutting disc (1)

• Insert the retaining bolt (3) from below through the wear plate, the blade and the cutting disc

• Place the hex nut (4) on the bolt from above and tighten it firmly (for torque see section

"Torques").

• Repeat this process for all blades, including those on the blade drums

• After fitting the blades, fold the protective device down again

Pos: 29.34.21 /BA/Wartung/M ähwer ke/M esserschr aub / M esserschnellverschluss/Beschr eibung M esser wechsel M esserschr aubverschl uss Hinweis @ 71\mod_1306221707374_78.docx @ 644013 @ @ 1

Note

• The cutter blades of anticlockwise rotating cutting discs / blade drums are different to those

of clockwise rotating ones. Make certain the direction of rotation is correct when installing!

• The arrow on the cutter blades must match the direction of rotation of the corresponding

cutting discs / blade drums

• The locknut (4) used to secure the retaining bolts must not be used more than once

Pos: 29.34.22 /BA/Wartung/M ähwer ke/M esserschr aub / M esserschnellverschluss/Beschr eibung M esser wechsel Best.-Nr. @ 72\mod_1306221763858_78.docx @ 644041 @ @ 1

Order No. for clockwise rotating blade: 139-889

Order No. for anticlockwise rotating blade: 139-888

Pos: 29.34.23 /BA/Wartung/M ähwer ke/M esserschr aub / M esserschnellverschluss/Beschr eibung M esser wechsel alter nati v Best.-Nr. @ 72\mod_1306223454041_78.docx @ 644097 @ @ 1

Alternatively:

Order No. for roof-shaped blade (clockwise and anticlockwise threading): 139 800

Pos: 29.34.24 /Layout M odul e /---------------Seitenumbruch---------------- @ 0\mod_1196175311226_0.docx @ 4165 @ @ 1