XIII - 5

Maintenance - Air Conditioning and Heating

BMII-134

Use the white float to check the amount

of coolant.

Some loss of coolant through the hoses in the climate

control system is unavoidable. Check the coolant level

every 100 hours. To do this, keep the engine running and

the climate control system switched on (and turned to

maximum cooling) and check the inspection window (2) in

the desiccator (1).

If the white float is at the top, the coolant level is O.K.

If the white float is at the bottom, you must top up the

coolant (specialised workshop)

Use the blue indicator bead to check the

moisture saturation.

Moisture in the coolant circuit is collected in the filter

desiccator.

If the indicator bead has a blue hue, the moisture

saturation is O.K.

If the indicator bead has a pinkish hue, the desiccator

must be changed (specialised workshop).

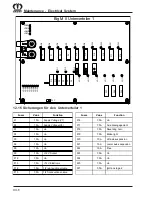

BMII-135

BMII-136

2

1

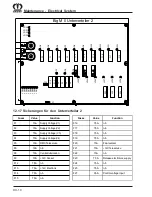

13.9 Collector / Drier

The ambient temperature must be

above the set thermostat temperature

(u1°C) for the compressor to

switch on.

Since an operating over-pressure is present inside the coolant

collector it manufacturing and testing is subject to the

Druckbehälterverordnung (pressure vessel code).

In this code the pressure vessels are classified according to

the permissible operating over-pressure p in bar, its capacity

in liters and the pressure capacity product p x l into test group

II.

According to § 10 of the Druckbehälterverordnung (pressure

vessel code) these pressure vessels are subject to a recurring

examination by an expert according to § 32. In this case,

recurring examinations consists of external checks, ususally

at vessels which are in operation. The coolant collector must

be checked visually twice a year in connection with the

inspection. Particular attention must be given to coorosion

and mechanical damage. If the proper is not in proper

condition, it must be repaced for safety reasons, to make

sufficient provision for the protection of operators and others

due to the danger during handling or operation of pressure

vessels.

13.10 Checking State and Filling

Amount of the Coolant

Summary of Contents for Big M II

Page 2: ......

Page 4: ...Vorwort Notizen ...

Page 28: ...II 14 Safety ...

Page 35: ...III 7 Controls 3 7 Roof Console BMII 192 A B A Compartment B Airconditioning heating ...

Page 42: ...III 14 Controls ...

Page 64: ...VI 8 Cabin ...

Page 68: ...VII 4 Check before Start up ...

Page 74: ...VIII 6 Engine Operation ...

Page 100: ...X 20 Mowers 10 6 Front Mower Lubrication Chart EC 087 1 ...

Page 136: ...XII 16 Maintenance Electrical System ...

Page 148: ...XV 4 Belt Drive ...

Page 154: ...A 2 Appendix ...

Page 155: ...A 3 Appendix ...