VIII - 3

Engine Operation

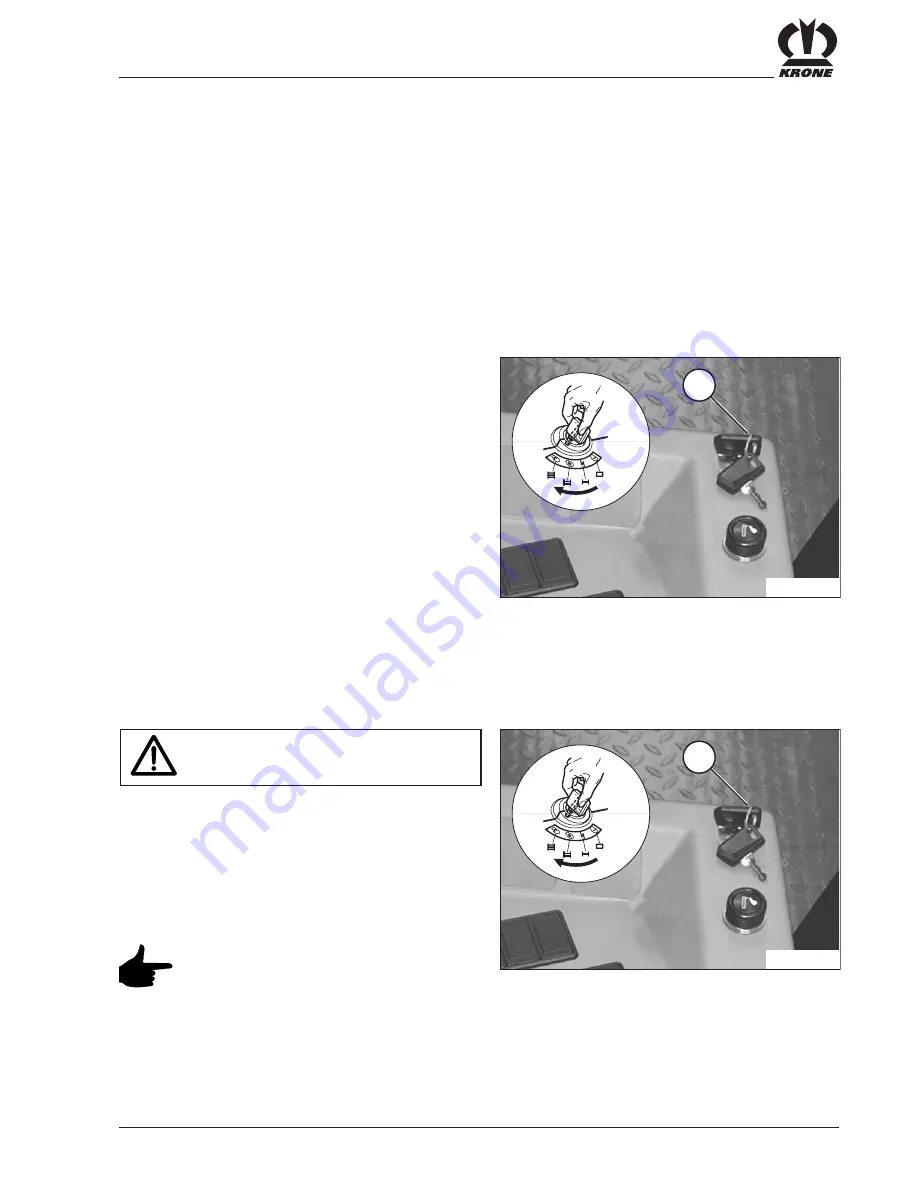

8.6 Starting Engine

Only start the engine from the operator's

seat.

Turn the starter switch to position II. Release the key

as soon as the engine starts. Never hold the key in the

start position for longer than 20 secs.

If you turn the key switch to position I before the engine

starts, wait until the engine has come to a standstill before

attempting to start again.

If the engine does not start within

20 secs., wait at least 2 min. before

attempting to start again.

BMII-177

1

BMII-177

1

8.5 Switching On Ignition

II

-

The ignition is switched on

The following

indicator lights

will illuminate:

Engine failure indicator light (2) for approx. 2 seconds

Job computer carries out internal system check

The basic display appears

Job computer carries out an internal system check.

The standard display appears.

8.4 Switching on the Circuit for the

Electronics

I

-

Circuit for the electronics is switched on

Summary of Contents for Big M II

Page 2: ......

Page 4: ...Vorwort Notizen ...

Page 28: ...II 14 Safety ...

Page 35: ...III 7 Controls 3 7 Roof Console BMII 192 A B A Compartment B Airconditioning heating ...

Page 42: ...III 14 Controls ...

Page 64: ...VI 8 Cabin ...

Page 68: ...VII 4 Check before Start up ...

Page 74: ...VIII 6 Engine Operation ...

Page 100: ...X 20 Mowers 10 6 Front Mower Lubrication Chart EC 087 1 ...

Page 136: ...XII 16 Maintenance Electrical System ...

Page 148: ...XV 4 Belt Drive ...

Page 154: ...A 2 Appendix ...

Page 155: ...A 3 Appendix ...