X - 7

Mowers

Setting the Roller Spacing

Loosen the lock nut (1) (spanner size 24) and turn the

adjusting nut (2) (spanner size 46) on the threaded

spindle (3).

Turn clockwise = lager spacing

Turn anticlockwise = smaller spacing

Tighten the lock nut again.

10.2.8 Setting the Roller Conditioner

(optional equipment / Big M CRi)

General

The roller conditioner is intended for operation in legumes

and other leaf vegetables.

The conditioner intensity is set using adjusting spindles (1)

which are used to change the spacing and application

force of the rollers. The minimum spacing between the

rollers should always be at least 2 mm.

BM300110

1

BM300290

2

1

3

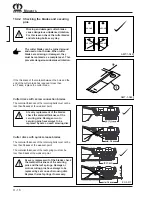

Always check the conditioner roller (1) for damaged

V-tines (2) before operation.

Straighten bent tines.

Replace broken tines.

Check bearing pins and bushing on tine mountings. To

avoid losing tines, replace bearing pins and bushings in

good time!

The conditioner shaft turns at up to

approx. 1000 r.p.m. Bent and broken

tines cause unbalanced rotation. For

this reason replace broken V-tines

immediately.

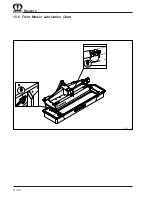

10.2.7 Setting the Conditioner Cover Plate

(Big M CV)

The conditioning effect of the mowing crop can be in-

fluenced by adjusting the conditioner cover plate using the

screw (1). Turning clockwise increases the conditioner

effect with an increase in power consumption. Turning the

screw anticlockwise reduces the conditioning effect.

Adjust the conditioner cover plate with the adjustment

pin (1) in side mowers.

SFM-P011

2

1

2

1

BM201301

Summary of Contents for Big M II

Page 2: ......

Page 4: ...Vorwort Notizen ...

Page 28: ...II 14 Safety ...

Page 35: ...III 7 Controls 3 7 Roof Console BMII 192 A B A Compartment B Airconditioning heating ...

Page 42: ...III 14 Controls ...

Page 64: ...VI 8 Cabin ...

Page 68: ...VII 4 Check before Start up ...

Page 74: ...VIII 6 Engine Operation ...

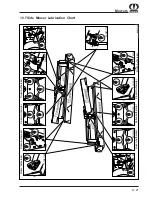

Page 100: ...X 20 Mowers 10 6 Front Mower Lubrication Chart EC 087 1 ...

Page 136: ...XII 16 Maintenance Electrical System ...

Page 148: ...XV 4 Belt Drive ...

Page 154: ...A 2 Appendix ...

Page 155: ...A 3 Appendix ...