O

r

i

g

i

n

a

l

o

p

e

r

a

t

i

n

g

i

n

s

t

r

u

c

t

i

o

n

s

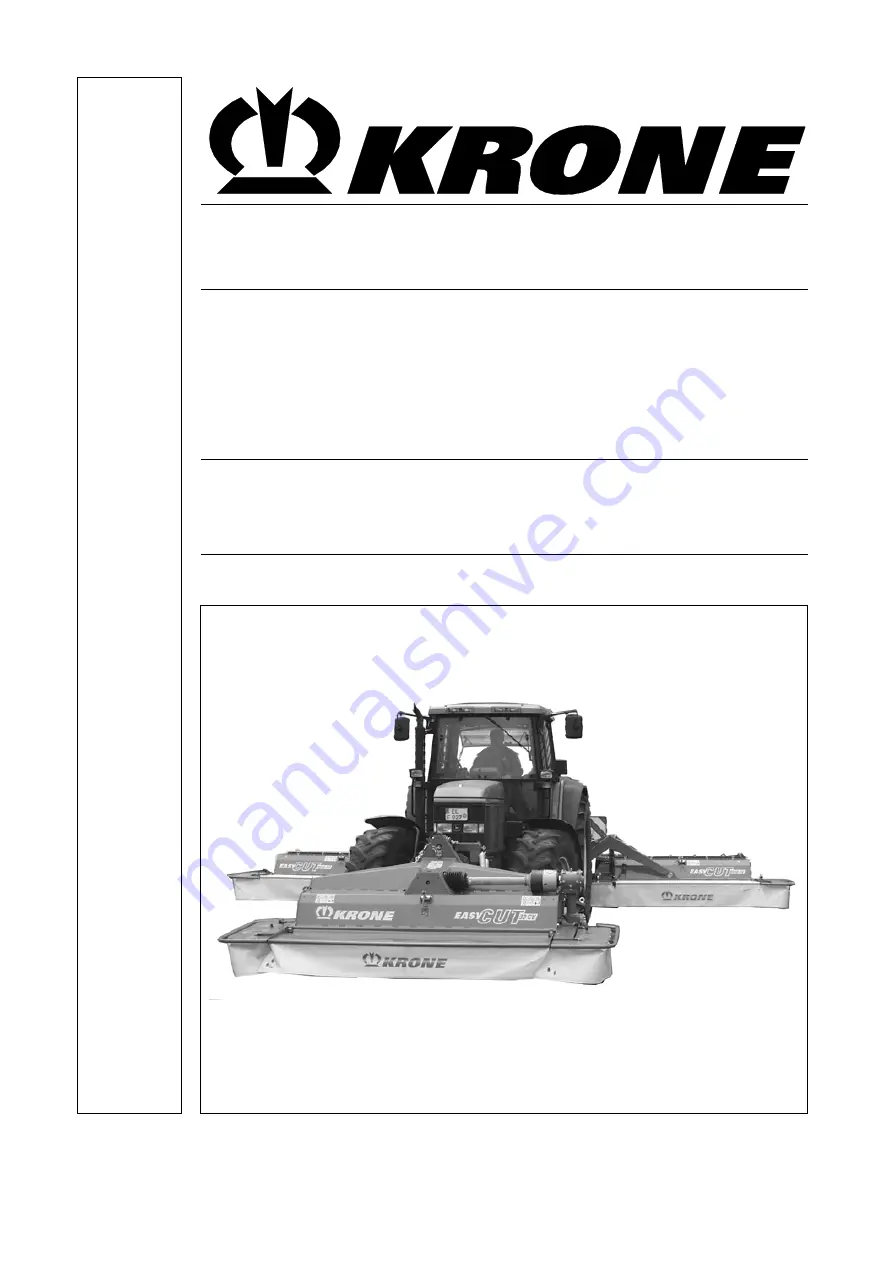

Disc Mower

<v>T-Typ1</v>

EasyCut 7540

</v>

<v>T-Typ2</v>

EasyCut 9140 Shift

</v>

<v>T-Typ3</v>

EasyCut 9140 CV

</v>

<v>T-Typ4</v>

EasyCut 9140 CV Collect

</v>

<v>T-Typ5</v>

EasyCut 10000 Shift

</v>

<v>T-Typ6</v></v>

(

<v>T-abMasch.-Nr.</v>

from serial no.

</v>

: 819 340)

<v>T-Bestell-Nr.</v>

Order no.

</v>

: 150 000 005 04 en

<v>B-Titelbild</v>

</v>

29.06.2011