Maintenance

71

Pos : 25.13 /Ü berschrif ten/Ü berschrif ten 2/ A-E/ Anzugs drehmoment e über I nnensechs kant @ 45\ mod_1277106415765_78. doc @ 411230

10.4

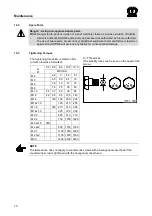

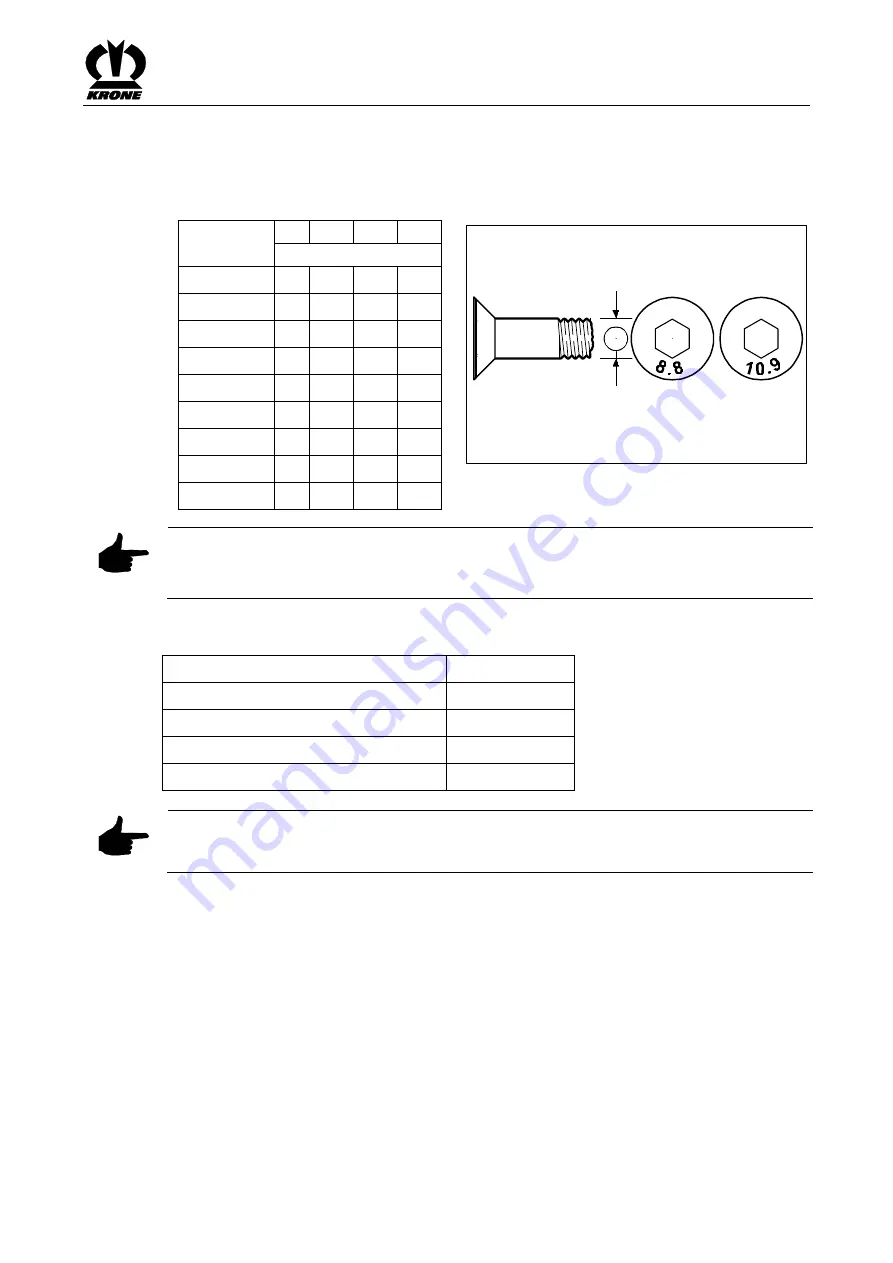

Tightening Torques (Countersunk Screws)

Pos : 25.14 / BA/ Wart ung/Drehmomente / Anzugs moment e/Dr ehmoment e über Innens ec hs kant @ 45\ mod_1277106232328_78.doc @ 411205

The tightening torque M

A

is stated in Nm

(unless otherwise indicated).

A = Thread size

(The stability class can be seen on the head of the

screw.)

A

Ø

5.6

8.8

10.9

12.9

MA (Nm)

M 4

2.5

3.5

4.1

M 5

4.7

7

8

M 6

8

12

15

M 8

20

29

35

M 10

23

39

58

67

M 12

34

68

100

116

M 14

108

160

188

M 16

168

248

292

M 20

340

488

568

A

BM 400 0234

NOTE

The table above applies only to countersunk screws with hexagonal socket heads and metric

threading that are tightened by the hexagonal socket head.

Pos : 25.15 /Ü berschrif ten/Ü berschrif ten 3/ A-E/ Abweic hendes Drehmoment @ 0\ mod_1196950054171_78. doc @ 15312

10.4.1

Deviating Torque

Pos : 25.16 / BA/ Wart ung/Selbstf ahr er/Gr undmasc hine/ Abweic hendes Drehmoment Eas yCut @ 3\mod_1204885737515_78.doc @ 73465

Screws / nuts

MA [Nm]

Nut for cutting disc flange

850

Nut for shear protection (rotary hub)

300

Bearing housing for cutting disc

50

Bearing housing for blade drum

50

Pos : 25.17 / BA/ Wart ung/Mutt ern und Sc hrauben (50h) anzi ehen @ 0\ mod_1196949864530_78. doc @ 15293

Note

Regularly check that nuts and bolts are tightly in place (approx. every 50 hours) and tighten

them if necessary.

Pos : 25.18 / BA/-----Seit enumbruc h------ @ 0\ mod_1196175311226_0. doc @ 4165