RUNNING GEAR OPERATION

32

Operating instructions • Load Carrier • 505410638-02 • 07/2019

!

WARNING

Improperly connecting and disconnect-

ing the supply and control connections

poses a risk of accident!

Improperly connected compressed air and

electrical lines affect driving and braking

behaviour and can lead to accidents.

► Observe the connection sequence of

the lines when hitching and unhitch-

ing.

► Always close the coupling heads with

the protective caps after unhitching

the brake lines.

For axle and brake control as well as air

and power supply, the trailer is equipped

with various connections on its front side.

The supply and control connections on the

coupling support of central axle trailers are

designed as a socket.

On turnframe trailers, the supply and con-

trol connections are fastened to the draw

fork as a strand with plugs.

1

2

3

4

5

6

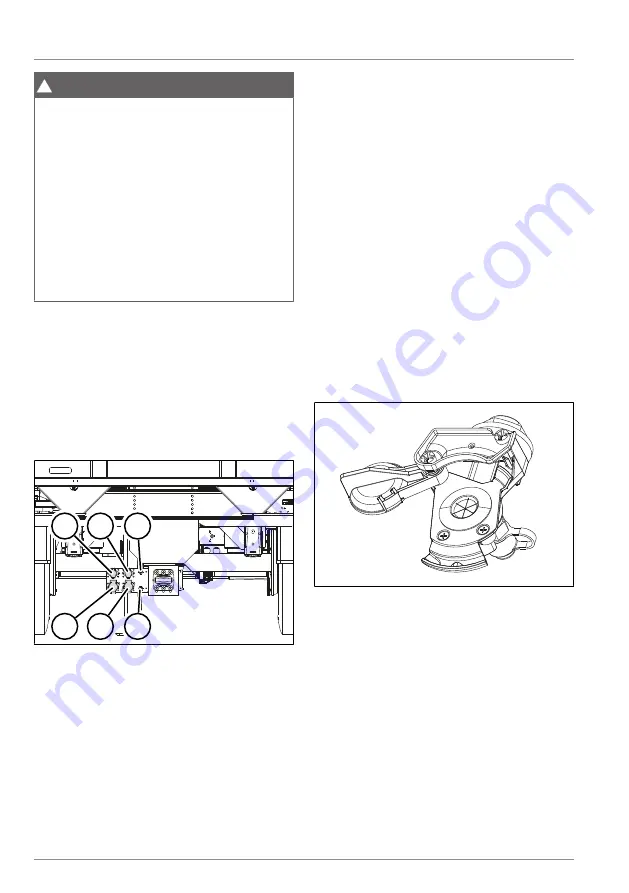

Fig. 5-13:

Supply and control connections

on the central axle trailer

1

Vehicle lighting socket N ISO 1185, 7-

pin (black)

2

Vehicle lighting socket S ISO 3731, 7-

pin (white)

3

Supply compressed air coupling (red)

4

Brake compressed air coupling (yel-

low)

5

Vehicle lighting socket ISO 12098,

15‑pin

6

Brake EBS socket power supply ISO

7638

More information about the plug and

socket assignment can be found in the

technical data

(see "13.2 Plugs and socket pin

Coupling

Depending on the design, the following

couplings may be installed:

○

Standard coupling heads (standard),

○

Duo-Matic coupling and

○

C-coupling heads.

Connecting the standard coupling

Fig. 5-14:

Example of standard coupling

head

þ

The parking brake on the tractor unit is

applied.

þ

The parking brake on the trailer is ap-

plied

(see "5.9.2 Parking brake", pg. 37)

► Check the cleanliness and integrity of

the sealing surfaces on the coupling

heads. Clean if necessary.

► Always connect the brake compressed

air coupling (yellow) first.

► Connect the supply compressed air

coupling (red).