Instruction Manual KG-253

12

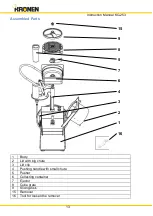

Parts and Description

Body (1):

built out of stainless steel; fundamental base for the vegetable

slicer.

Lid (2):

the removable lid makes sure that there is no unintended con-

tact with the slicing chute.

Pushing handle (4):

with the pushing handle it is possible to push the

food with a constant force into the big slicing chute. In the pushing han-

dle is a smaller chute for the smaller food.

Collecting container (6):

the sliced products fall into the collecting con-

tainer. To make the cleaning easy the collecting container is removable.

You can also use the collecting container for optional cube gates.

Ejector (7):

the ejector is responsible for the transport of the processed

food to the ejection chute.

Pusher (5):

the pusher is located at the smaller chute and the pushing

handle. It makes it easier to get the material through the slicer.

Slicing disks (9):

the slicing disks are responsible for the right of the

food. They come in different versions which are to be installed depend-

ing on what the result should look like.

Cube grate (8):

the cube grate needs to be installed at the collecting

container. With the adequate slicing disks the food will be processed

into cubes.

Remover (15):

the remover is responsible for slicing a hole in big mate-

rial, so that the slicing process doesn’t get interrupted.

Tool (16)

: The tool is intended for loosening the Remover.