11

EN

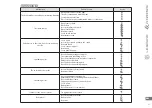

Maintenance schedule

After each ride

Every 25 h

Every 50 h

Every 100 h

Clean the leg pipes and anti-dust seals

Search for upper pipes scratchings

Grease the seals using Teflon oil (e.g. Brunox Deo)

Check air pressure

Check if the main screws are tightened to appropriate moment

(Nm)

1st service

2nd service

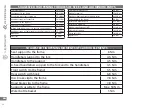

THE 1

ST

SERVICE INCLUDES:

Inspection of fork operation/cleaning and greasing the bushing/line and cover of the remote blockade/control of torque value (tightening), control of

air pressure/checking the fork for scratchings, dents, breakages, bends and wear signs.

THE 2

ND

SERVICE INCLUDES:

1

st

s deinstallation/cleaning of the entire fork/greasing anti-dust seals and oil scrapers, greasing top lids of the remote blockade and range

regulation/tightening top lids of the air valve by greasing, inspection for air leaks/torque (tightening) control/adjusting to personal preferences of the

cyclist. Information about the locations where 1st and 2nd services are performed can be obtained in an authorised service station.

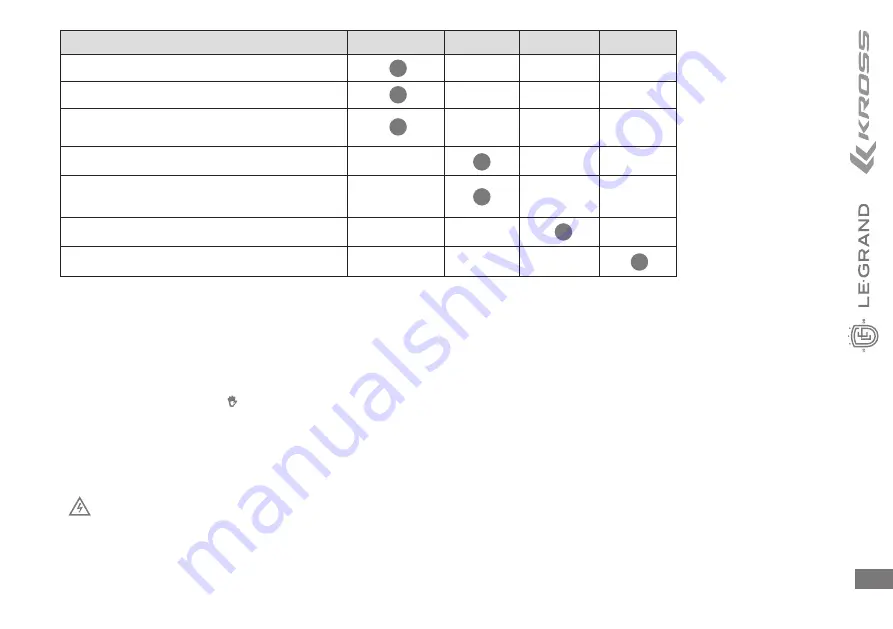

Shock absorber adjustment

BLOCKING SYSTEMS

The function of “blocking” forks is designed for minimising bicycle wobbling (“pumping”) during riding, when the cyclist is not seated on the seat or during climbs. The fork shall not be

100% blocked. There still remains a movement range of a few milimeters, necessary for the operation of the fork locking system. This system protects the cyclist if he or she forgets to

unlock the fork after entering a difficult terrain.

Despite the above, never block the fork during riding in a difficult terrain, riding downhill or jumps. It carries the risk of damage to the fork caused

by its compression under heavy load.