- 30 -

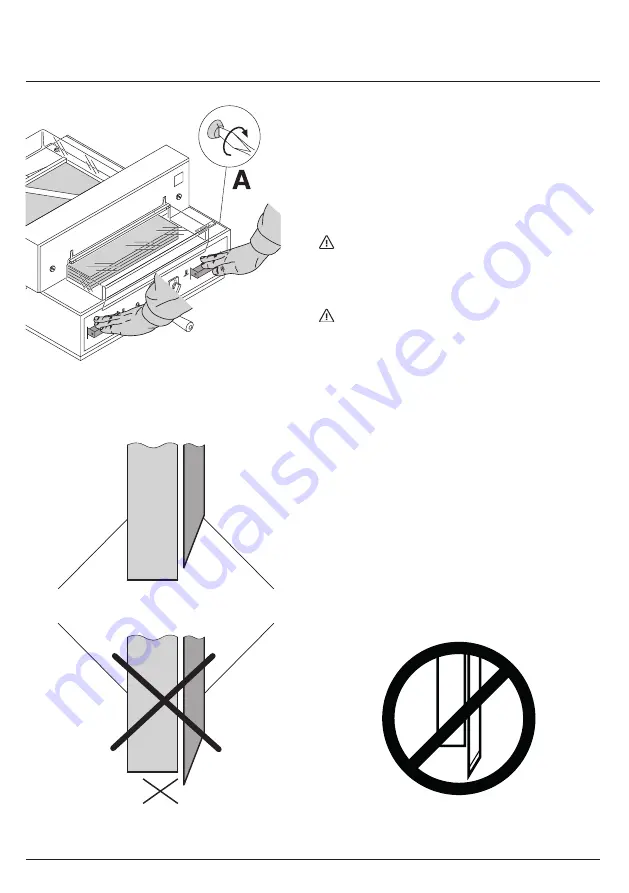

Paper cutting test. If the last sheet or several

sheets are not completely cut, gradually turn

the knob for blade depth adjustment (

A

)

¼ turn to the right until the paper is cut along

the entire length. Do not set too low as blade

will become blunt sooner.

Danger! Do not turn main switch to

position

"

0

"

whilst blade is moving

upwards or downwards!

Risk of injury!

Danger! Blade must always be covered

by the pressing bar (see picture below on

the left).

Clamping

Blade

OK

OK

Blade and cutting stick replacement