- 18 -

C

K

W

L

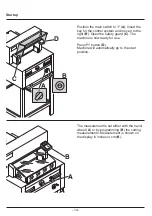

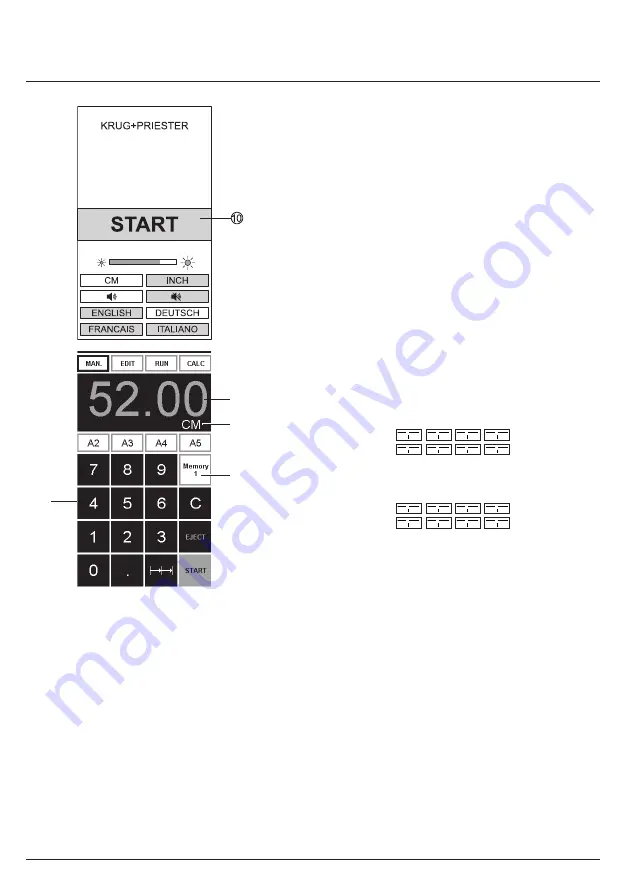

Start machine

•

Main switch

D

to position "I", insert the key

F

for the control panel and turn to the right.

Start screen appears

The following functions are changeable:

Brightness

CM/INCH

Touchtone ON/OFF

Language

•

Press START

J

backgauge

G

moves

to the rear and searches for the reference

position, wait until a measurement

is shown in the display

C

4855 = 45.00 cm, 17.717 inches

5255 = 52.00 cm, 20.472 inches

6655 = 61.00 cm, 24.016 inches

•

The DIN and free programmable

measurements are recallable with the

respective buttons

W

.

Memory 1: A2, A3, A4, A5,

Memory 2: A6, A7, B3, B4

Memory 3:

Memory 4:

and in inch

Memory 1: 4¼“, 5 ½“, 7“, 8 ½“

Memory 2: 11“, 12“, 14“, 17“

Memory 3:

Memory 4:

Operation